What are the advantages and disadvantages of differential measurement technology?

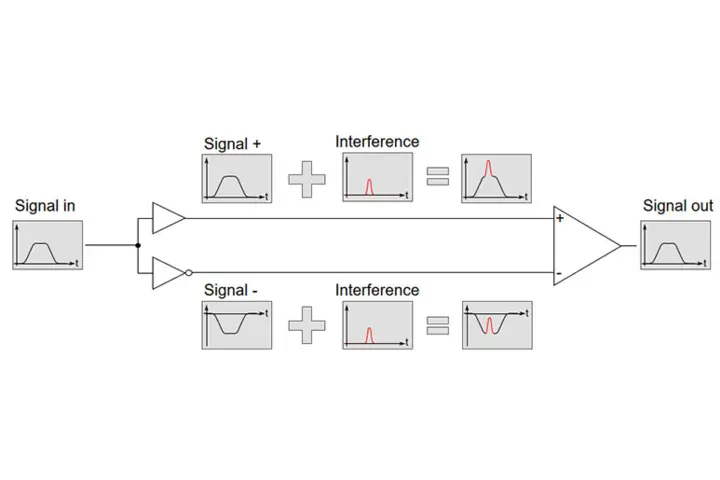

The main advantage of differential measurement technology compared to single-ended technology is that it is much less susceptible to disturbance variables. Each individual signal in the differential transmission is equally susceptible to disturbance variables and can take on a falsified absolute value, depending on the interference. The difference between the two distorted signals corresponds to the signal to be transmitted (signal out) that, in this case, is not influenced itself because both signals are falsified to precisely the same extent. This is illustrated in the chart below.

The disadvantage of this type of signal transmission is that it requires more technical effort: all of the components must be designed for this technology.

What components are required for a differential measuring chain with piezoelectric sensors?

A differential measuring chain is made up of differential sensor technology, suitable cable solutions and differential charge amplifiers. Piezoelectric sensors generate charge signals corresponding to the physical variables to be measured. The same amount of positive and negative charge is always polarized on the piezoelectric material.

With a differential piezoelectric sensor, both charge signals – positive and negative – are captured. These signals are then forwarded to a differential charge amplifier where the difference is generated and converted into a signal (voltage, current, IEPE, etc.) that can undergo further processing.

What are the typical application areas for differential measurement technology?

Differential measurement technology is mainly used in challenging areas where extreme reliability and the highest possible resolution are required, and in environments with high potential for electromagnetic interference (EMI). Typical application areas include thermoacoustics (such as gas turbine monitoring) or optimization of industrial burners using acoustic thermometry.