What methods are available to measure torque?

The method for measuring torque depends on the application; torque can be measured either directly or indirectly.

The method for measuring torque depends on the application; torque can be measured either directly or indirectly.

When exact and reproducible measurements of torque need to be determined dynamically, and for dynamic as well as static long-term measurements, strain gage technology provides the basis for direct measurements on the test object with the help of rotating transducer shafts. A torque-measuring element captures, amplifies, and digitizes the torque that is to be measured. The digital measurement values are conditioned and processed for a variety of outputs. Most modern torque-measuring shafts use telemetry for contact-free energy and data transmission.

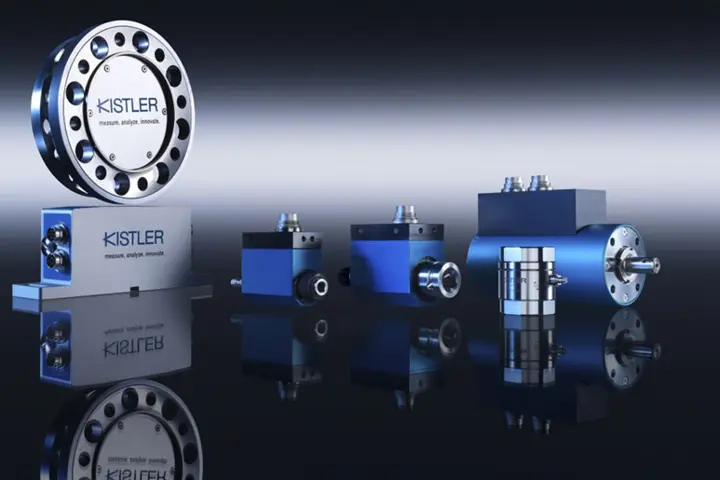

Torque sensors are integrated directly into the production process to monitor fastening processes. Contact-free torque-measuring flanges allow direct measurement of a drive’s torque in the powertrain.

Piezoelectric reaction torque sensors are a proven and effective solution for measuring reaction torques in applications that require large measuring ranges, extremely high overload protection, and high resolution. Even when mechanical loads are very high, these sensors can capture very small torque fluctuations with no difficulty.

Torque measurements play a key part in many industries: they are especially important in mechanical engineering, for manufacturers and operators of test stands, and in many sectors of the manufacturing industry.

Torque is an important measurand in the development process for combustion engines, drives, and pumps. It is used to define performance, efficiency, and friction coefficients.

In research and development, industrial process monitoring and quality assurance, torque measurements provide a reliable basis to guarantee that test objects ranging from threaded joints to drives meet maximum safety and efficiency requirements.

Advanced testing and simulation procedures play a fundamentally important part in the automotive and aerospace industries, in forming processes, in plastics processing and in the renewable energy sector: in all these applications, they can boost the efficiency of drives – and therefore of complete systems as well. Targeted efficiency improvements lead to lower energy consumption. The results: costs are cut significantly and companies improve their market positioning over the long term. Torque measurements are becoming increasingly important in the context of electromobility.