New machining method revolutionizes turning

Ceratizit's experts have now developed a new machining method that is set to revolutionize turning. High Dynamic Turning (HDT) and the FreeTurn tools included in the system allow the cutting head to move freely - so the approach angle of the cutting edge can be chosen freely at any point during the machining operation. FreeTurn tools feature a new type of indexable insert that can consist of several different cutting edges. This breakthrough allows both pull- and push-type machining of workpieces. Chip breaking can also be optimized, and the chip can be moved out of the cut zone.

HDT offers a key advantage: only one tool is needed to carry out all the familiar turning operations such as roughing, finishing, contour turning, face turning and longitudinal turning. This means that every contour of a turned part can be produced with no need to change the tool. The result: from now on, parts can be fully machined with just one single FreeTurn tool instead of the large numbers of different tools that were required in the past. Tool changes as well as empty tool runs are vastly reduced - leading to increased productivity. And as yet another benefit, tool costs are slashed.

"The values obtained with measurement technology from Kistler are plausible. Industry trusts them. And that means we can supply machine and spindle manufacturers with reliable values that they too can trust."

Dr. Uwe Schleinkofer, Head of R&D Cutting Tools

Less force is applied thanks to this innovative concept

A further advantage of HDT is the new angle of approach, which directs the cutting force vertically through the tool into the spindle. This reduces the load on the machine, making it possible to work with higher process parameters. The free choice of approach angle also extends the life expectancy of the cutting edge.

The first tests have been completed successfully, so the system is currently undergoing the release procedure for series use. For this purpose, Ceratizit's developers need detailed and reliable values for the forces that occur in the system. This data is essential to improve their understanding of the tool properties in the cutting process. Manufacturers of machines and controls as well as CAM software providers have a particular need for this information so they can drive their developments ahead towards their defined goals.

Extensive series of tests with support from Kistler

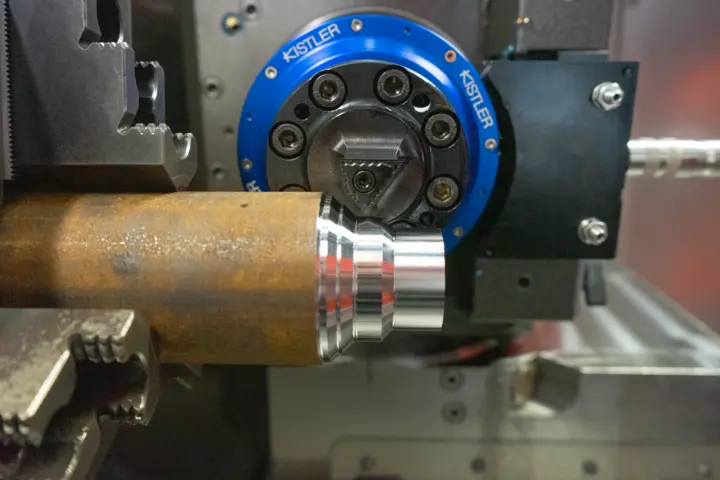

Ceratizit has already been putting its trust in solutions from Kistler for over 30 years. And in this project too, products from the Swiss measurement technology specialist have played a key part. The 9171A 4-component rotating cutting force dynamometer (RCD) was used to measure the cutting forces. This measuring instrument features a modular structure and is compatible with all commonly used machine spindles. It measures the forces acting on the cutting edge in all three axes, and can also calculate the torque on the basis of these values. Piezoelectric sensor technology gives the RCD a very high sampling rate coupled with sensitivity across an extremely wide force range. These assets guarantee that the measurement data is meaningful as well as accurate. Transmission of measured values and energy is contact-free, so wear is eliminated.

The measuring chain was completed with the 5238B signal conditioner, which is responsible for the energy supply, signal transmission and system control in the test setup at Ceratizit. Measurement range settings and adjustments to the low-pass filter are made manually on the signal conditioner or via the serial interface. System activation and data acquisition are handled via the DynoWare software from Kistler. The measurement signals are also available as analog voltage signals (±10 volts).

Cutting force measuring instrument from Kistler supplies reliable values

The tests were carried out during summer 2019 at the Innovation Center of Ceratizit Austria GmbH in Reutte (Austria). The first objective was to approach the maximum performance capability of the HDT system. Different values for the feed rate and cut depth were selected for this purpose. The steepness of the approach angle for the FreeTurn tool was then gradually increased. The dynamometer from Kistler supplied detailed and reliable values for the forces occurring during this process. This data was compared to the results for a conventional turning tool of type PCLNL 2525 M12.

Onsite support for the project was provided by Lukas Janotta, the Kistler application engineer responsible for cutting processes. He advised the Ceratizit engineers as they performed the series of tests. The DynoWare software from Kistler was used for detailed visualization, recording and analysis of the forces occurring during the tests. This made it possible to validate the results from previous simulations with real measurement values. As the end result, the customer gained in-depth insights into cutting force conditions that were previously hidden.

![A turn for the better [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-393e.webp)