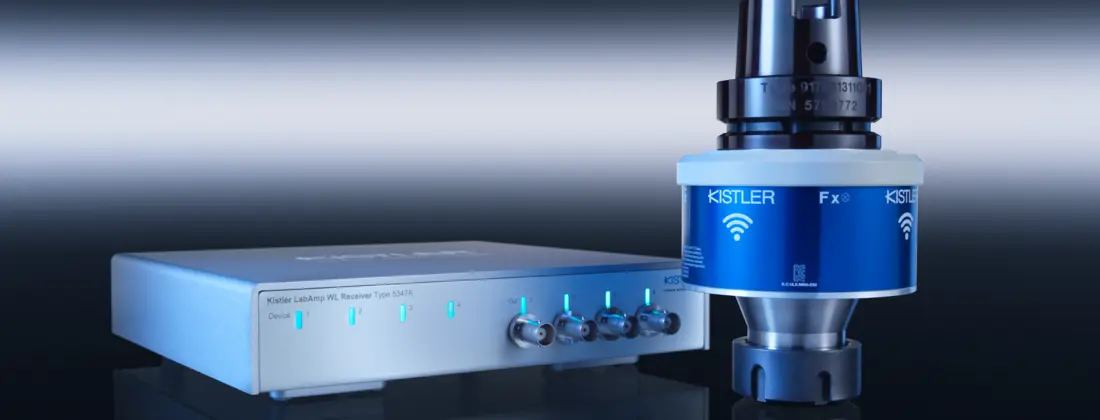

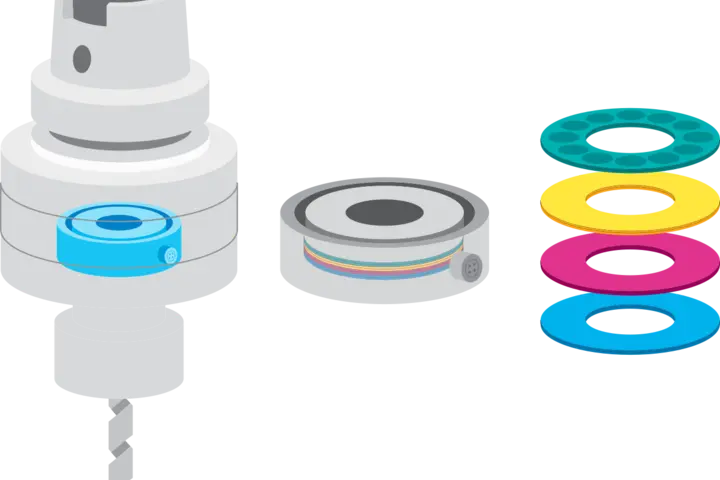

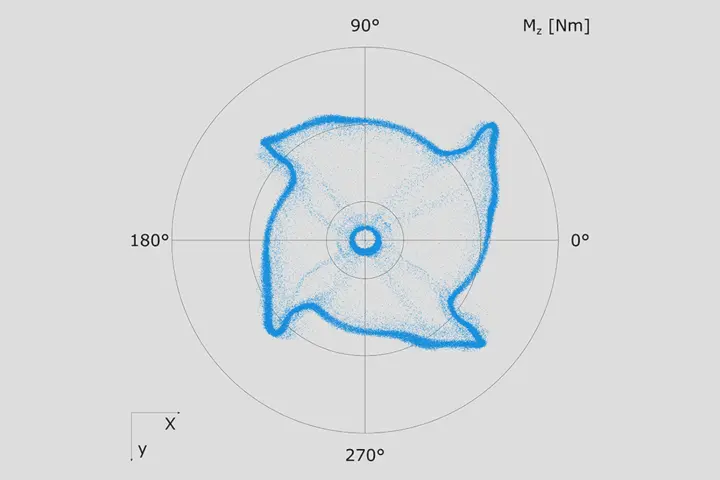

Wireless rotating dynamometers (wireless RCDs) with piezo technology open up new possibilities for high-precision measurement and process analysis, especially in combination with new software: the Piezo Tool System (PTS) app.

Thanks to wireless communication, cables in the machine room are now a thing of the past – the receiver box can stream the data directly to a PC. Specifically developed for industrial applications, the PTS app offers all the analysis and measurement functions needed for efficient evaluation of data volumes – no matter how large. Data can also be used for multiple functions: even on small tools, for example, each tooth engagement can be viewed with high resolution, or tool life can be maximized.

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSGalleryPreview_96x64/wireless-rcd-signal-quality_48482.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSGalleryPreview_96x64/wireless-rcd-trend-analysis_48480.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSGalleryPreview_96x64/polarplot-milling-double-edged-tool_48512.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSGalleryPreview_96x64/meshing-frequency-milling_48511.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSGalleryPreview_96x64/thread-cutting-torque-axial-force-comparison_48510.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSGalleryStandard_720x480/9170A_48515.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSGalleryPreview_96x64/9170A_48515.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSGalleryPreview_96x64/9171A_48514.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSGalleryPreview_96x64/measuring-chain-9170a-9171a_48513.webp)

![A turn for the better [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-393e.webp)

![Tapping into success [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-474e.webp)