To gain insights into the complex physics inside cargo containment systems (CCS) partially filled with liquefied natural gas (LNG), the Dutch research institute MARIN has developed a new facility named The Atmosphere (ATM). 100 pressure sensors from Kistler inside the ATM deliver accurate feedback on sloshing wave impacts ‒ a major contribution to improving CCS designs not only for LNG but also, potentially, for hydrogen in the near future.

Natural gas is a cornerstone of cleaner and more sustainable energy provision at global level. Pipelines and shipping are both used to transport this fuel from its natural origins to its destination of use, but shipping is the more economical method ‒ especially over longer distances. Liquid gas is carried at temperatures of around ‒162°C by special-purpose ships known as LNG tankers, sometimes recognizable because of their partly visible spherical tanks. More than 600 of these vessels are already in service throughout the world, and the market is expected to continue growing in the coming years. In terms of design, there is still plenty of scope for optimizing the tank geometry of these ships, but this requires groundbreaking research into the fundamental physical mechanisms behind the processes involved. One phenomenon that is not yet fully understood is sloshing ‒ the motion of a liquid (LNG in this case) inside a container due to external forces (such as the ship's movements): and this is where MARIN plays a key role.

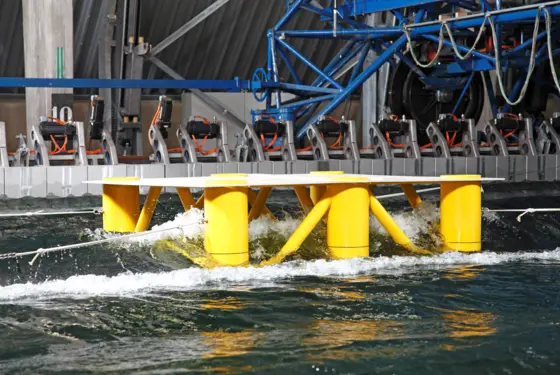

The Maritime Research Institute Netherlands (MARIN) in Wageningen is one of the world's leading marine research centers. Since 1932, MARIN has built up a vast stock of expertise based on a combination of numerical simulations and experiments performed in large-scale facilities comprising various basins for ship model tests, together with on-board measurement and testing. With the backing of a public-private partnership including Dutch universities, industry partners and federal funding, a new globally unique facility was commissioned in 2016. The Atmosphere (ATM) is a giant research facility capable of creating different atmospheric conditions by varying the pressure (0.02‒10 bar), temperature (15‒200°C), type of gas (He, N2, SF6 and water vapor), relative humidity (0‒100%) and other parameters that influence the sloshing dynamics in a real LNG tanker. The ATM consists of an autoclave with an outer diameter of 2.5 m and a length of 15 m ‒ people can actually enter it, but events inside are usually observed through one of the 17 inspection windows.

![Measuring wave impacts under extreme conditions [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-496e.webp)