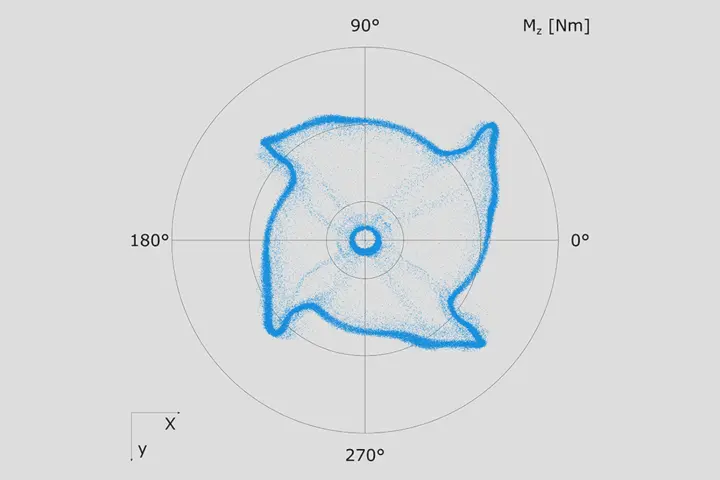

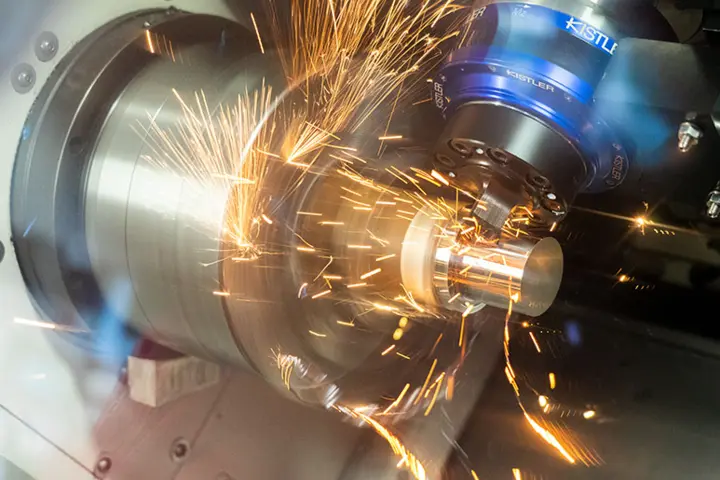

Whether operators want to develop new cutting force processes or improve existing ones, cutting force measurements are front and center: In both research and machining development, they provide crucial data for matching equipment perfectly to the cutting process. The data provides information on the tool’s influence on the cutting force as well as information about the cutting process itself.

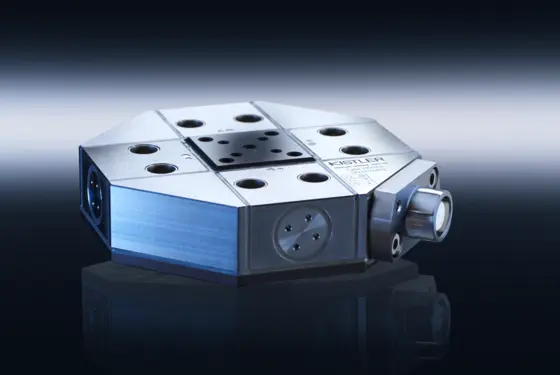

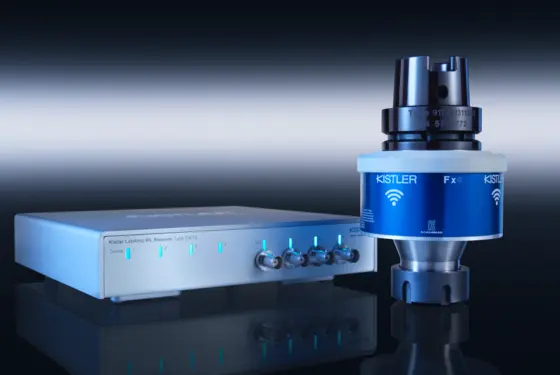

This is where stationary and rotating dynamometers from Kistler come in: The piezoelectric sensors measure cutting forces during the machining process with high accuracy. Based on the acquired figures from dynamometers, operators can evaluate and choose the optimal tools, clamping devices, cooling lubricants and materials for their cutting processes. This way, the data helps boost the quality and cost efficiency of the tools and cutting processes as well as extend the tools’ lifetime.

Also, Kistler’s dynamometers enable operators to examine and optimize raw materials: They deliver information about the characteristics of materials, which in turn allows their evaluation with regards to the cutting processes. The data can also help verify individual simulations and process models or be used to establish unique product features.

![Cutting force measurements in research and development [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-002e.webp)

![The right technology to monitor machining processes [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-437e.webp)

![Cutting force measurement leads to superior tooling concept [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-074e.webp)

![Evaluation of cooling lubricants under operating conditions [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-671e.webp)

![Cutting force measurement leads to sophisticated machining processes [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-057e.webp)

![Analyzing highly dynamic forces [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-165e.webp)

![More robust, with higher precision and longer lifetimes [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-302e.webp)

![Tapping into success [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-474e.webp)

![A turn for the better [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-393e.webp)