Satellite jitter, or blurring of the images originating from micro-vibrations, is a severe deviation source that affects the geometric accuracy of high-resolution imagery. Recent years have seen major advances in terrestrial observation – accompanied by a dramatic increase in the need to measure the earth's surface and atmosphere with ever greater precision.

The quality of these images would have been unimaginable only a few years ago. Critical steps in achieving this progress include the reduction of micro-vibrations on board satellites. Every satellite requires numerous drives, position controls, reaction wheels, actuators and cryo-coolers: the list could go on. These devices comprise mechanical components that cause vibrations when they operate. Micro-vibrations consist of extremely small accelerations of very low intensity. Measuring them is a challenging task. High-frequency jitter can be measured with piezoelectric force sensors, charge amplifiers and low-noise accelerometers and dynamometers.

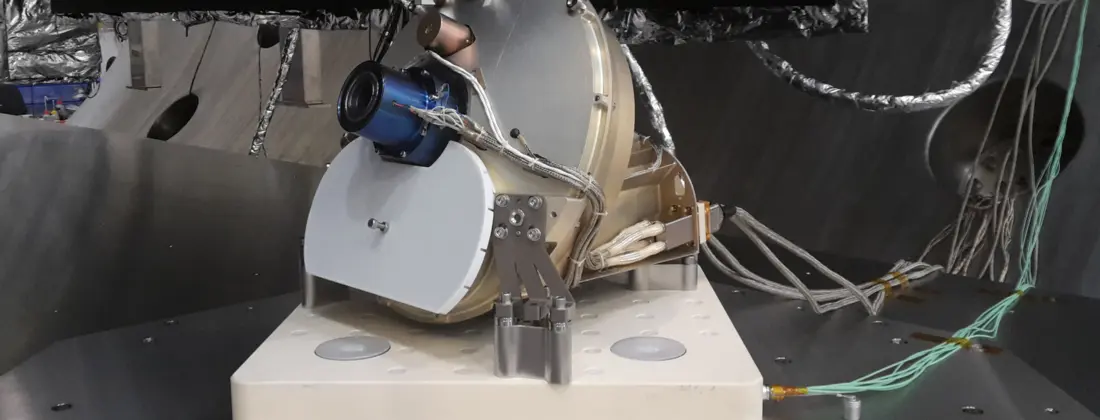

Recent innovative designs using ceramic top plate dynamometers allow higher sensitivities, higher frequency ranges and the possibility of water cooling optimized for reaction wheel jitter and cryo-cooler micro-vibration applications.

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/back-to-the-moon-44074.webp)

![Space brochure [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-096e.webp)

![Smooth performance near absolute zero [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-420e.webp)

![AS9100 D certificate granted to the facility of the Kistler Group site in the U.S. [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/999-240e.webp)

![Micro-vibration modeling and measurement on a Sentinel 4 UVN calibration assembly using a piezoelectric 6-component force dynamometer [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-366e.webp)