The emergence of a large-scale hydrogen economy presents challenges in terms of the measurement technology to be deployed. Diffusion and accumulation of hydrogen leads to increased embrittlement of materials; furthermore, diffusion of hydrogen into sensor measuring elements can lead to distortion of measurement results.

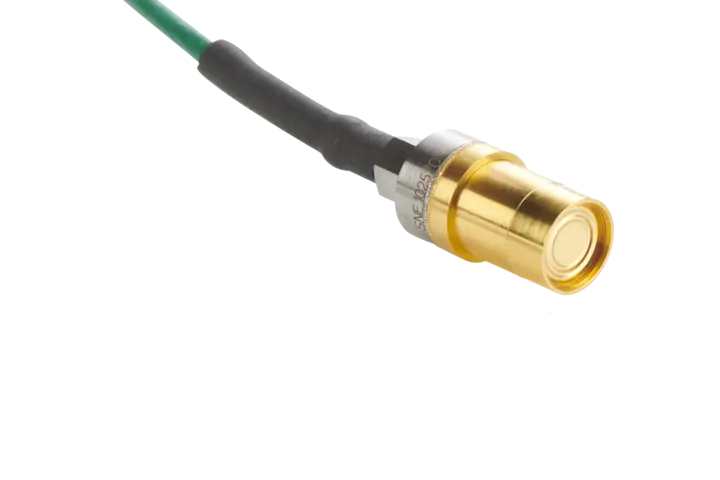

Combustion engines operated with hydrogen or alternative H2-based fuels are practically emission-free, and they pave the way for decarbonized mobility. Engine developers need hydrogen-resistant sensors in order to optimize hydrogen combustion. Kistler has responded by developing the 4012A hydrogen pressure sensor, which can be used for gas exchange analysis, as well as pressure measurement in the low-pressure fuel supply rail of hydrogen engines.

Ongoing fuel cell development opens up an additional approach to achieving a sustainable energy supply. The new 4012A sensor can be used to monitor hydrogen pressure in the low-pressure range of a fuel cell. To do this, the piezoresistive absolute pressure sensor features two measuring ranges: up to 20 bar and 50 bar.

![Hydrogen combustion: Kistler launches a new absolute pressure sensor to measure hydrogen pressure [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-960e.webp)