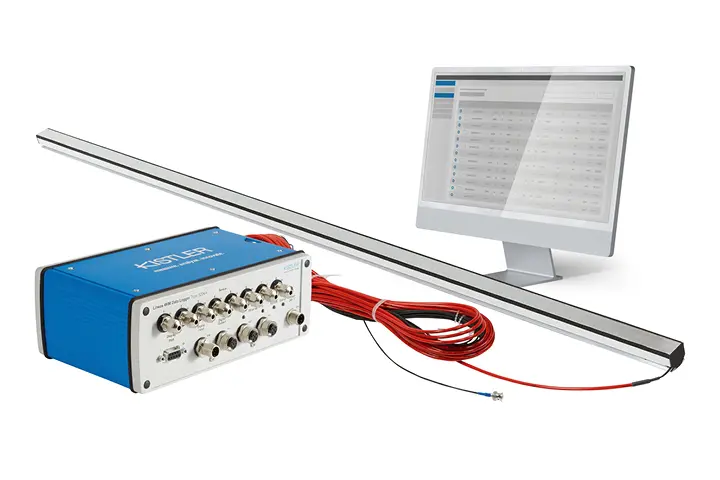

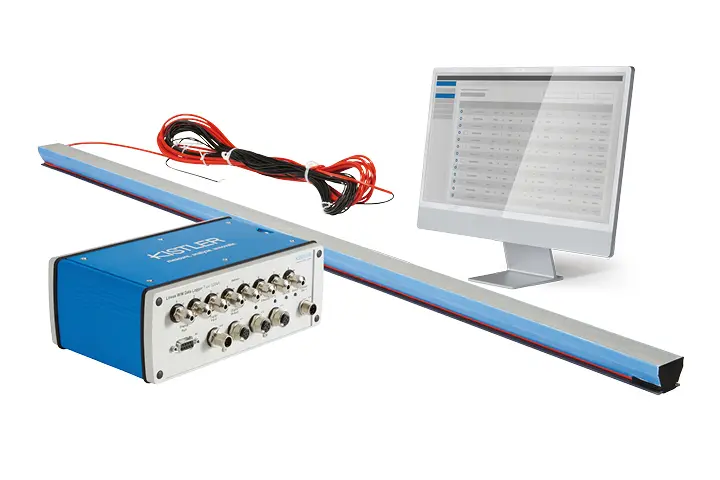

Our Weigh In Motion solutions use Lineas high-precision quartz crystal sensors, which are known for their consistently high performance under all traffic and weather conditions.

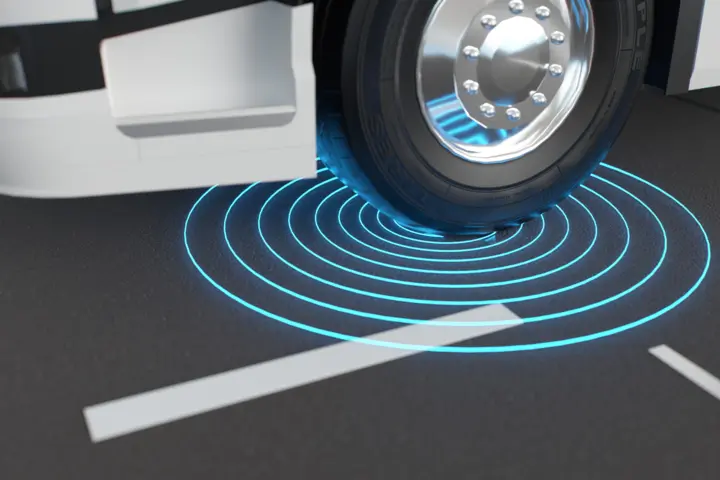

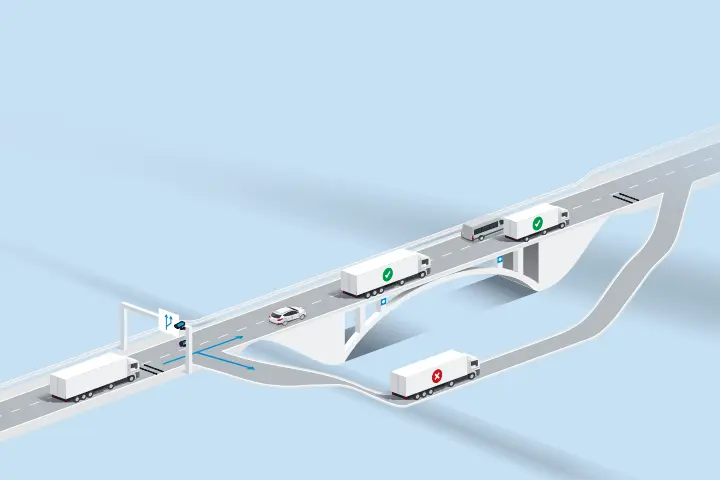

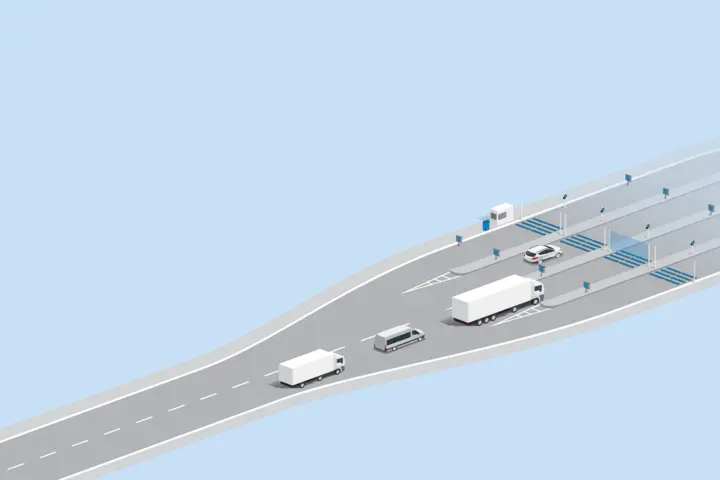

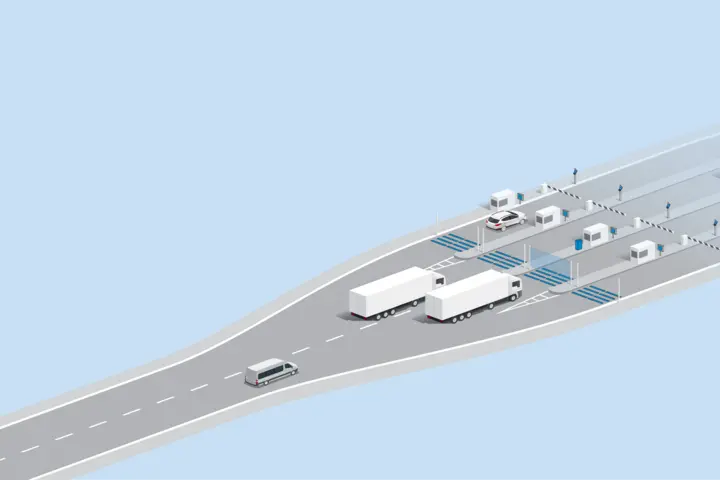

Aging infrastructure, increasing traffic and overloaded vehicles pose a threat to our society and call for countermeasures to keep roads and bridges safe. Advanced Weigh In Motion (WIM) systems from Kistler enhance traffic safety, help to maintain road quality, and protect bridge infrastructure.

System integrators around the world choose Weigh In Motion solutions from Kistler as part of high-level traffic management systems. Thanks to their reliability and robustness, high degree of accuracy, and effortless integration, our solutions are used to safeguard and sustain roadways and structures of all kinds.

![Servizi di pesatura dinamica WIM [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/kistler_shutterstock_100912969_14600.webp)

![Weigh In Motion [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/200-746e.webp)

![Certificate of origin for Lineas [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/lineas-certificate-of-origin_49596.webp)

![‘Copycats’: a risk for users, and a problem for the industry [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-762e.webp)

![A look behind the scenes at Kistler’s sensor production facility [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-306e.webp)