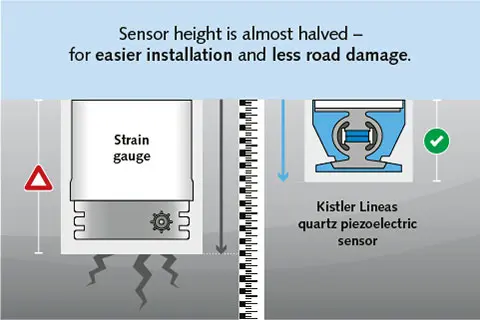

Road installation depth

Quartz piezoelectric sensors for Weigh In Motion applications are less complex in design than strain gauges, so they are smaller and more compact. This reduces the effort needed to install them under the highway's surface: they can be installed in the road pavement at depths of as little as 55 mm (2.17 in), so the work can usually be completed in one or two days with minimal disruption to traffic. The dimensions of strain gauges, on the other hand, have to be increased in order to lower tensions – and, as the U.S. Department of Transportation notes in its "Weigh-In-Motion Pocket Guide": "The strain gauge strip sensor installation currently recommends 3-inch-deep channels (= 76 mm) cut in pavement for installation. This installation requirement limits the applicability of strain gauge strip sensors for thin pavement types." Kistler also offers a new service – Structural Road Analysis (SRA) – to help customers identify and qualify the most suitable locations for installing their WIM systems.