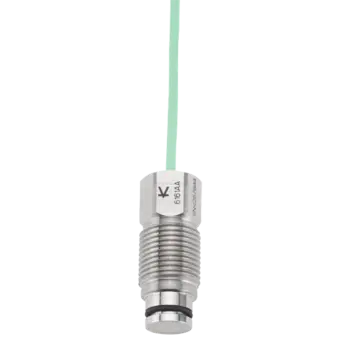

Mold cavity pressure sensors for RTM method (max 200 bar, ø9 mm front) / 6161A

6161A

These mold cavity pressure sensors for low and high pressure RTM processes are calibrated for vacuum measurement.

Main features / advantages

- Particularly suited to industrial use in HP-RTM tools

- Welded diaphragm design resists against penetrating resin

- Calibrated for vacuum measurement

- Exchangeable cable

- Mounting bore sealed by O-ring

The Type 6161AA sensors comprise a sensitive 4 mm diaphragm sensor welded into a robust 9 mm cartridge. The welded annular gap prevents penetration by low-viscosity resins and sensor signal distortion as the result of a force shunt. An O-ring ensures that a vacuum can be achieved inside the tool while preventing low-viscosity resin from entering the gap. Cables are exchangeable to facilitate repair. The pressure acts directly on the front of the diaphragm and is in turn conveyed to the measuring element, which then emits an electric charge proportional to the pressure exerted. This is converted by an amplifier into a voltage, ranging from 0 ... 10 V, that is then present on the amplifier output.

Loading

Loading