Natural gas serves as an alternative energy source and is transported by special LNG (Liquefied Natural Gas) tankers around the world. Their tank structures have to withstand movements of LNG – the so-called sloshing – even in heavy swells. Kistler provides research laboratories worldwide with application-specific pressure sensors – including IEPE and very compact solutions – for sloshing testing and assessment.

Natural gas can only be transported efficiently in liquefied form. Cooling the gas to –162°C (–260°F) makes its volume 600 times smaller, so it can be transported by LNG tankers. Wind and waves can cause movements of the LNG in partially filled ship tanks. These movements – known as sloshing – can affect ship stability and may expose the internal tank membranes to heavy loads.

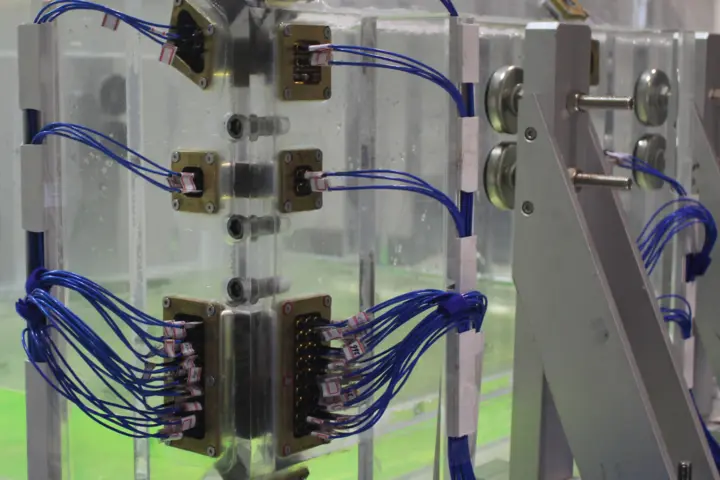

Many research laboratories throughout the world study the sloshing-induced dynamic loads on the tank structures of LNG tankers. Sloshing testing and assessment procedures usually involve a rectangular 2D model of an LNG tank on a hexapod; small-scale 3D models are also used. The pressure sensors are usually deployed in cluster configurations on the tank model wall, at various locations where severe impacts are most likely.

![Solutions for hydrodynamic testing [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-258e.webp)