The 3C, electrical and electronics industries face growing requirements in the areas of quality assurance, material testing, error detection in manufacturing, increasing efficiency and quality improvement. Simultaneously, costs need to be optimized and further reduced. Here, the computer, communications and consumer electronics industry (3C) is under significant pressure, due to its technical innovations, short product life cycles, very brief ramp-up times for new production lines, and yet, maximum quality requirements. Mass production, extensive product variety, intense competition, tight delivery times: the challenges in this industry sector are enormous.

In manufacturing and the development of production processes, force, pressure, acceleration and torque each play a decisive role. Deviations from defined parameters can result in damage and faulty products. Given the high speed of production, monitoring systems are needed that can meet the dynamic requirements of today's production equipment. The combination of highly sensitive sensor technology and process monitoring systems is the key to reliable acquisition, visualization and evaluation of measurement data. This provides valuable information about the quality of manufactured components – and also ensures that faulty parts are detected and/or sorted out at an early stage.

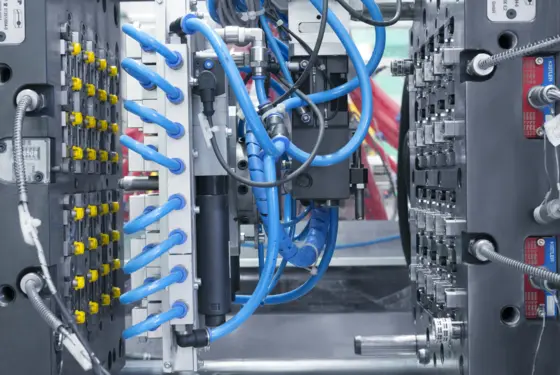

We support you from the product development phase (e.g. by fast, data-based validation of manufacturing processes) up to the product testing phase. Our solutions can monitor complex production processes such as the injection molding of components for smartphones and tablets or the assembly processes for a vast range of products (smartphone displays are just one example). Our systems can also perform high-precision product testing, including tactile behavior testing on control elements, spring testing, vision inspection and more.

![Cut costs [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Download_original/cut-costs_49521.svg)

![Increase productivity [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Download_original/increase-productivity_49519.svg)

![Competitive edge [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Download_original/competitive-edge_49520.svg)

![Force Sensors [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-262e.webp)

![In-process quality control as a key to success [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-904e.webp)

![Inline process monitoring for stamping [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-745e.webp)

![Making excellent connections [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-383e.webp)

![Technological lead with piezoelectric sensors from Kistler [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-905e.webp)

![Process monitoring for highly automated production [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-207e.webp)