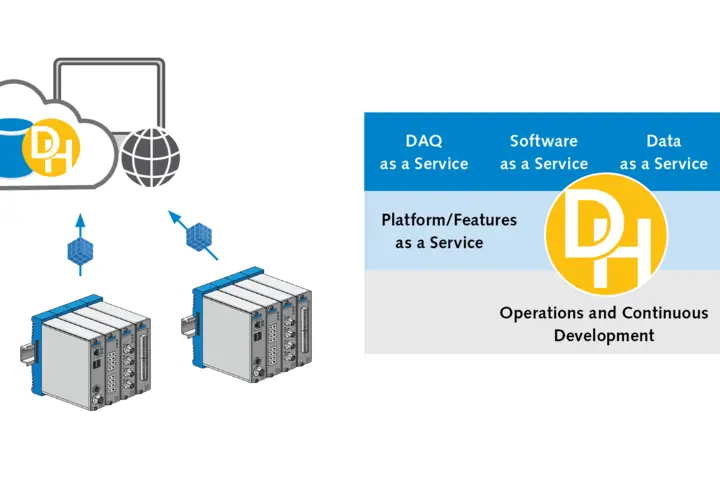

Winterthur, February 2022 – “From sensor to cloud” – this is the vision that Kistler intends to realize in the 2020s. What is almost always the starting-point for developments and processes supported by measurement technology? The necessary data, of course. So data provision and integrity are the most critical factors. Going forward, the software components involved will increasingly be operated as flexible, highly available services in the cloud. So the motto really ought to be: “From cloud to sensor”. The new Kistler Digital Hub is where all data from highly dynamic distributed measurement setups will come together.

How is digitalization driving the evolution of measurement technology? To answer this question, let's look at an example. Kistler has collaborated with Swiss Federal Railways (SBB) on a current project to improve brake maintenance on local trains. Until now, every single wheel had to be equipped with a sensor and measured, and then the values were recorded on paper. But thanks to the new digitally-based solution, four sensors can be deployed at the same time. The benefit: now, only one measurement is needed for each bogie. Evaluation and reporting are also handled automatically. Originals of generated reports and related raw data are stored in a digitally sealed package that is protected against modifications. As a recent case of data manipulation in SBB's own operation showed, this is quite an important feature.

But the benefits of the new digital solution go far beyond more efficient and reliable brake force measurements. Thanks to the modular design principle, multiple brake force measuring systems can be cascaded to create a larger system solution. Going forward, this will open the way to semi- or fully-automated measurements of entire trains in just one step. Extending the measuring channels and using pressure sensors can deliver another advantage: in parallel with the real brake force built up on the wheel, the pneumatic pressure can also be measured to gain information about the condition of the entire braking system. Highly structured raw data collected for all historical measurements is also available for later analysis. This forms the basis for services such as condition-related maintenance, provides knowledge about the product lifecycle and – ultimately – leads to improved design of components such as bogies.