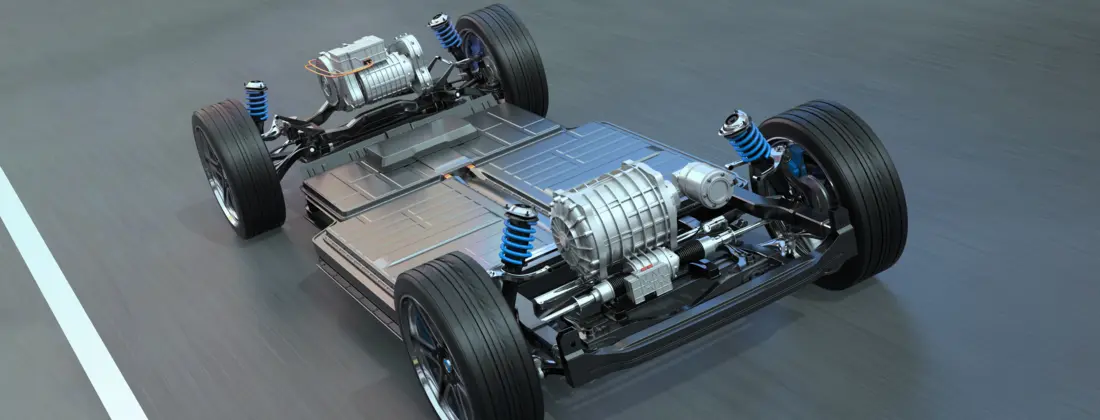

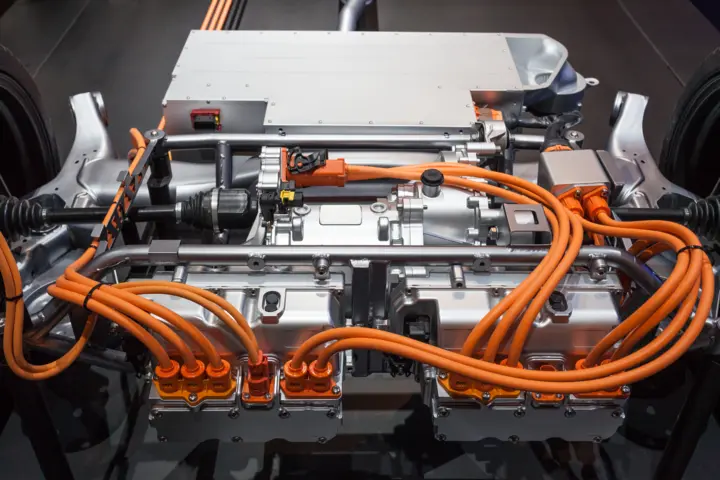

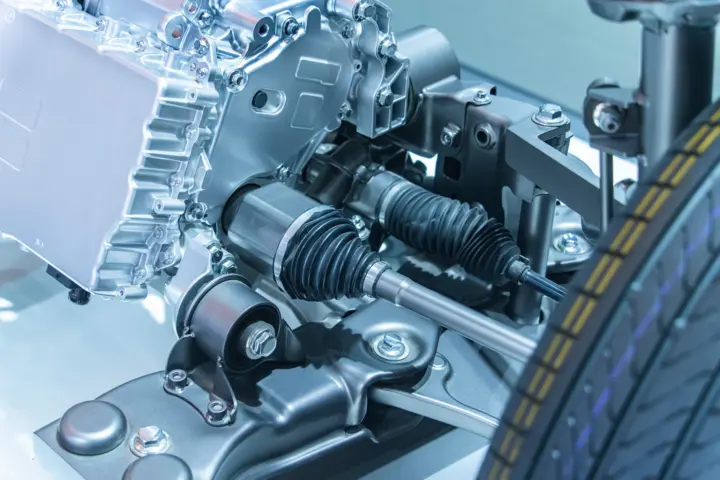

Electric/hybrid powertrains are complex systems made up of a varying number of components: e-motor, converters, inverters, batteries and eventually even a combustion engine. A precise understanding of how these components interact and how these interactions are influencing each other is indispensable in the characterization of their performance.

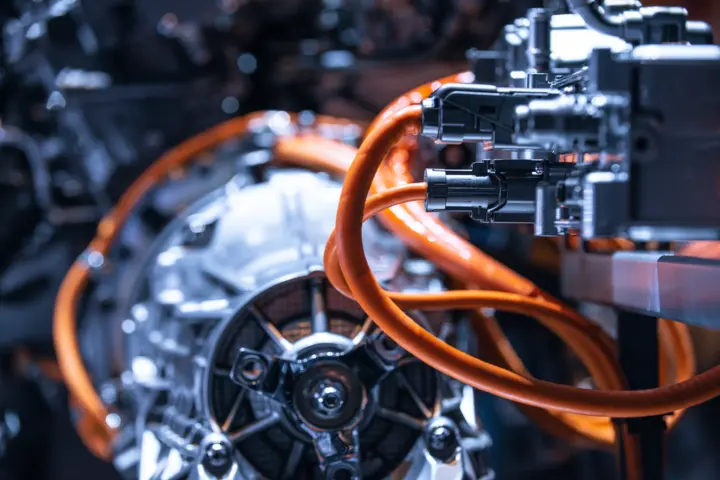

Therefore, dynamic vehicle testing in a high-voltage environment with constantly changing states of electrical parameters and thermal behavior requires a reliable solution that can be adapted to changing scenarios. Monitoring temperature accurately across the entire system and especially in batteries is an important topic and critical for overall performance in terms of energy efficiency and safety.