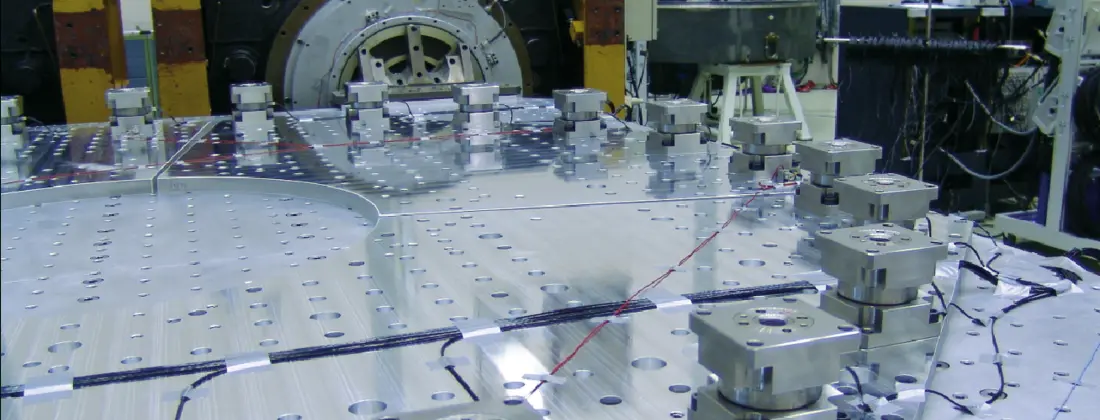

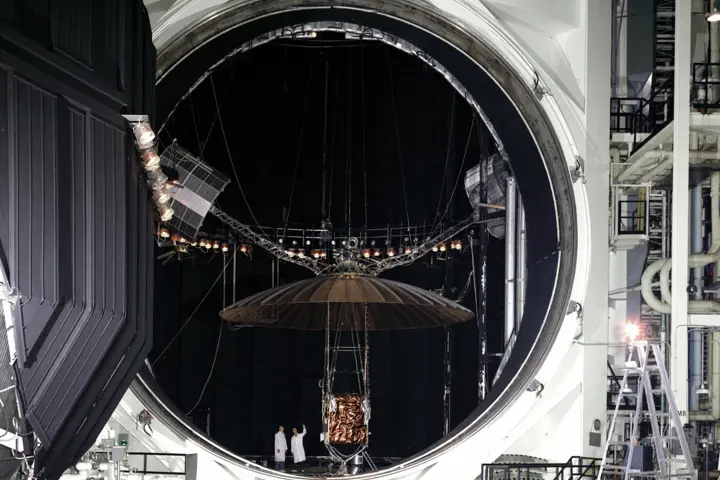

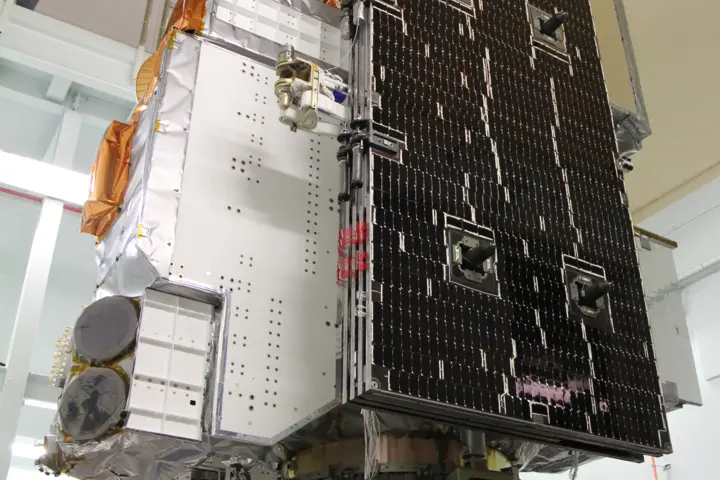

Telescope performance depends on stability in the nanometer range, so the stability of the fully instrumented backplanes is critical. They need to be tested in thermal vacuum chambers suitable for testing under cryogenic conditions, and designed to ensure unique thermal stability at temperatures below –250 °C (–420 °F). Testing in the vacuum chamber requires accelerometers and force sensors with ultra-low temperature capabilities.

Backplanes can carry the primary mirror as well as other telescope optics and the entire module of scientific instruments. Testing allows modification of the system so that the backplanes – and ultimately the telescope – can be isolated in the chamber. Some testing environments include a new, layered helium and nitrogen cooling system: this allows the backplanes to reach the low temperatures that simulate operating temperatures in space. They allow for cryogenic optical alignment and testing of multiple primary mirror segments in a process known as "phasing". Testing of this sort calls for accelerometers and force sensors with ultra-low temperature capabilities.

![Space brochure [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-096e.webp)

![Airbus [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-294e.webp)

![Smooth performance near absolute zero [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-420e.webp)

![AS9100 D certificate granted to the facility of the Kistler Group site in the U.S. [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/999-240e.webp)