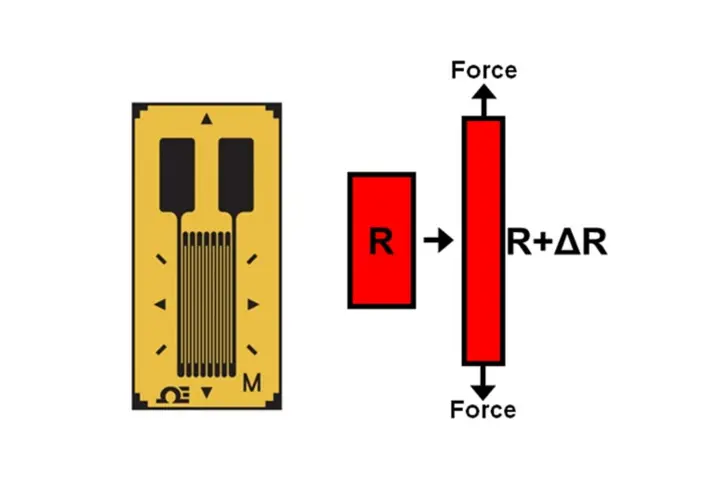

What is a strain gauge?

Strain gauges are metallic-electric measuring elements that precisely measure forces, loads, torque, etc., particularly in static processes. Strain gauges operate based on the physical effect by which the electrical resistance of a wire changes proportionally to the strain exerted on the wire when stretched or compressed. Strain gauges are used in sensors, force and torque sensors, load sensors (for scales), and other measuring devices. Strain gauges are frequently affixed to measuring bodies made of high-strength material.