Piezoresistive pressure sensors from Kistler are highly suitable for evaluating both static and dynamic pressure. Harsh conditions in test environments include extreme temperatures as well as high vibration and shock levels, so these sensors incorporate many design features that can easily overcome these challenges. The micro-machined silicon sensing element is fully isolated from the pressure media by a welded stainless steel diaphragm and a high-integrity seal assembly. The sensing element combines high stability with excellent repeatability. Piezoresistive transducers from Kistler are designed for survivability of up to 50 million full-scale cycles at 2 Hz; maximum pressure range capabilities of up to 350 bar (5,000 psi) or up to 10 bar differential (150 psi) are available, together with barometric pressure ranges.

Aircraft hydraulic system performance

Hydraulic systems perform multiple functions on modern aircraft. These include maneuvering and actuating the landing gear, brakes and flaps, and operating both primary and secondary flight controls, thrust reversers and spoilers. Hydraulic systems often have a direct impact on flight safety: landing gear, for example, must absorb landing loads to ensure stable operation. Because so many aircraft functions are critically dependent on hydraulic devices such as pumps, actuators, control surfaces and valves, this equipment must undergo intensive ground and flight testing.

Pressure ranges

Sensors to verify hydraulic system performance must be able to measure both static pressure and dynamic pressures of up to 2 kHz. The maximum pressure range capabilities required are up to 350 bar (5,000 psi) or up to 10 bar differential (150 psi), and barometric pressure ranges must also be available. These environments may also require high proof/burst pressures of up to 3 or 4 times full-scale pressure. Products in the Kistler portfolio can meet all these demanding requirements.Robust operational performance

Aircraft flight testing takes place in an environment where robust operational performance is often demanded, so sensors must be qualified at specific levels including shock as per MIL-STD-202G, Method 213B-1, Conditions E, C; and vibration at 50 g peak, 10 Hz to 2 kHz. Kistler's piezoresistive transducers are designed for survivability of up to 50 million full-scale cycles at 2 Hz.Stability/accuracy

Sensors used for critically important flight qualification testing must meet very high stability and accuracy requirements. Piezoresistive transmitters from Kistler are temperature-compensated over a range of –40 to 120°C (–40 … 250°F). They can achieve accuracy of 0.1% (full scale) with stability per year of 0.1% (full scale).

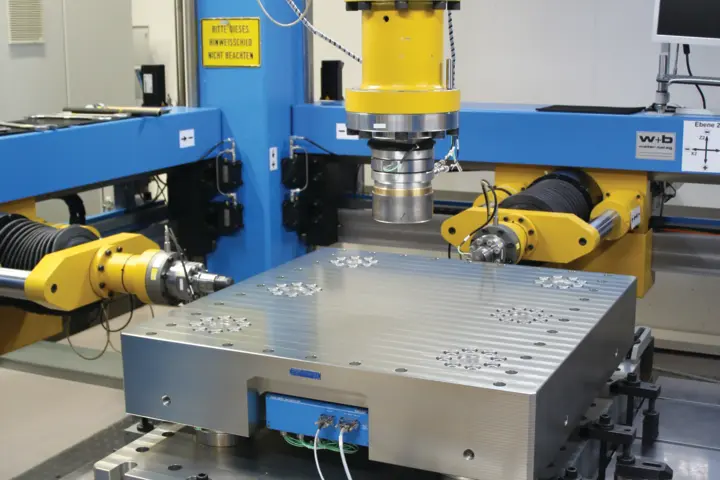

In-house calibration on Kistler's unique 3-component reference force press.

Need a consultation?

Our experts are just a click away.

Solutions for aircraft hydraulic system testing

Find out more about our sensors for ground and flight testing

![Customized landing gear dynamometer [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSGalleryPreview_96x64/customized-landing-gear-dynamometer-32528.webp)

![Solutions for aviation testing [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-213e.webp)