“Tool R&D requires great learning efforts, and it has to overcome major technological barriers,” says Lin Liangliang, R&D Director of the Cutting Tools Division at GESAC. “Tools play a decisive part in machining quality – but they are also consumables that are sensitive to unit costs. In that way, they differ from many other industrial products.” This makes it essential to evaluate tool properties in relation to downstream customer-specific machining scenarios.

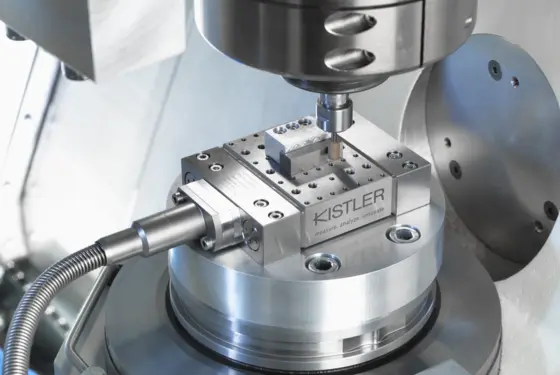

A successful R&D process requires measurement systems that can collect dynamic cutting force data for use as analytic evidence of the performance and condition of tools and machined materials. To meet this need, GESAC opts for dynamic measurement solutions from Kistler.

“Aided by our collaboration alliances with various Chinese universities, and based on recommendations from professors and industry experts, we launched our trials of Kistler products in 2009; we’ve now been using dynamometers from Kistler in our R&D for over ten years.”

Zhao Biaochun, Manager Product Testing and Analysis Division at GESAC

The company focuses on three main product categories: solid endmills, indexable cutting tools, and drilling tools. Samples of all products in each category must undergo testing of properties and durability as well as tests under working conditions at the end of the manufacturing process.

“Measurement results acquired with Kistler dynamometers have improved our ability to assess tools, especially drill bits – given that our previous approach was not sufficiently objective,” Zhao adds. Unlike turning and milling, chip removal in the drilling process occurs inside the tool, so it cannot easily be observed while machining is under way. In days gone by, experienced technicians used to base their speculations about the progress of chip removal on the noises made by a machine tool and its load, but such assessments were highly subjective and uncertain. Now, with the help of cutting force dynamometers, the engineers at GESAC can accurately measure the force indexes of a running drill bit and observe the subtle changes that take place in them. Zhao concludes: “Dynamometers from Kistler provide wide, high-precision measuring ranges. The assured quality of these products is one of the main reasons for our long-term partnership.”

Cutting performance comparisons in real time

Thanks to measurement data acquisition with Kistler solutions, GESAC is also able to perform in-depth tool comparisons. For example: if a conventional twist drill is used to machine a thin-walled aluminum alloy part for use in the aviation industry, the part can easily be deformed. By analyzing accuracy errors when drilling thin-walled workpieces, the R&D team at GESAC learned that cantilever deformation is directly related to cutting forces: smaller cutting forces mean smaller deformation and more precise hole sizes. A trepanning drill, on the other hand, has two innate advantages: first, its tool edges are subject to less disturbance from cutting chips during machining; and second, it applies smaller cutting forces. To compare how the two different drilling tools perform when machining thin-walled parts, the team analyzed the cutting force data collected with dynamometers from Kistler. The results indicate that trepanning drills apply significantly smaller cutting forces than twist drills, and they can deliver a much better surface quality for the machined parts.

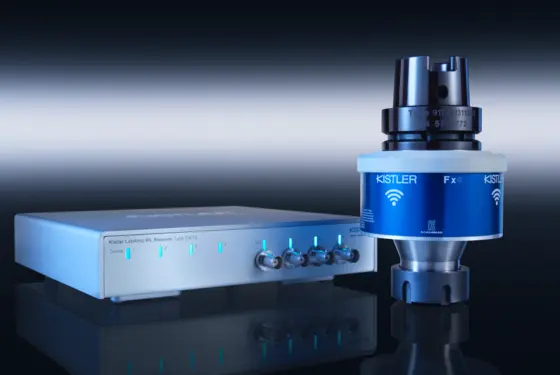

GESAC was also among the first customers in the world to try out the new wireless rotating cutting dynamometer (RCD) from Kistler. Thanks to this innovation, customers can transmit the measured cutting forces directly to their PC via wireless signal receivers – eliminating the intricate cable connections previously needed inside the machines. Like conventional rotating dynamometers, the wireless RCD (Type 9170B) features outstanding advantages such as high natural frequency, a wide measuring range, and the ability to measure real-time cutting forces through a rotating tool range. During the measurement, this dynamometer can immediately output the values of Fx, Fy, Fz and Mz, and then display the tangential force Ft and normal force Fn thanks to seamless software calculations. “We can even match measured data directly to the individual cutting edges of the corresponding tools. That allows us to determine the specific forces applied on each edge exactly, so we can use them more appropriately,” Lin Liangliang explains. His final words: “The Cutting Tools Division at GESAC will continue to play its part in advancing the supply chain of China's tool industry by upgrading its technical strength, and by living up to its service philosophy: `from end customers, and for end customers'.”