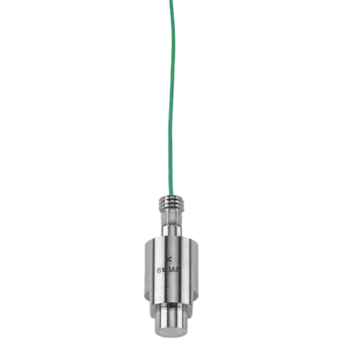

Cavity pressure sensors, direct measuring (ø6 mm, 1000 bar) / 6163A

6163A

These piezoelectric sensors are suitable for cavity pressures up to 1000 bar during the pressing and injection molding of low-viscosity plastics and resins.

Main features / advantages

- Pressure range: 0 … 1000 bar

- Exchangeable cable

- For compression molding and processing of thermosetting materials and rubbers

- Sensitive diaphragm sensor welded into sleeve

The Type 6163A family of sensors consists of a sensitive ø4 mm diaphragm design welded into a robust ø6 mm sleeve. The welded ring gap prevents ingress of low-viscosity resins and falsification of the sensor signal by a force shunt. Interchangeable cables allow a choice of cable types and repairs. The pressure acts over the diaphragm front of the sensor and is transmitted to the measuring element, which produces a proportional electric charge (pC = Picocoulomb). This is converted into a voltage of (0 ... 10 V) in the amplifier, and is then available as an amplifier output. These sensors are available in two versions for different types of cable. The coaxial version uses high-insulation cables that do not necessarily have to be laid in the mold. The practical single-wire alternative is based on a cable that can be cut to any length. The cut-and-grip connector can be connected during mounting in the mold. This makes both installation and servicing easier.

Loading

Loading