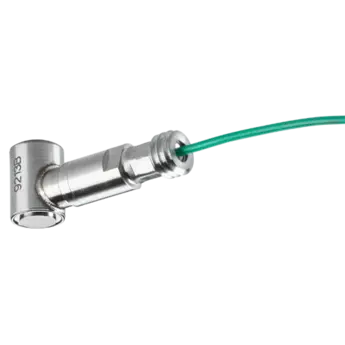

Cavity pressure sensors, indirect measuring (ø6 mm, 2.5 kN, 200°C), with M2.5 mounting thread / 9213B

9213B

These quartz force sensors are suitable for measuring indirect cavity pressure behind an ejector pin during the injection molding of plastics.

Main features / advantages

- Extremely compact cavity pressure sensor

- For cavity pressures up to 3000 bar

- Replaceable cable

- Available with single-wire technology

- Fastening thread M2.5

The Type 9213B miniature sensor offers high resolution and has extremely small dimensions, as well as a rugged, welded case. The charge signal (pC = Picocoulomb) output by the force sensor is converted in the Kistler charge amplifier or in a monitoring unit into a proportional output voltage that is largely independent of the length of the sensor cable. The maximum possible output voltage from the standard amplifier is 10 V. In the most sensitive range this gives 1 N/V. The replaceable cables allow a wide choice of connecting cables, including the single-wire version. With single-wire technology, an individual cable is shortened to the required length and connected to the connector using the proven cut and grip technique. With this arrangement, the mold serves as a shield for signal transmission. For multi-cavity applications, the sensors of Type 9213B are used without the Type 1839 single-wire connector. For 4-channel applications, Type 9213B is mounted with the Type 1708 multi-channel connector, and for 8-channel applications with the Type 1710 multi-channel connector.

Loading

Loading