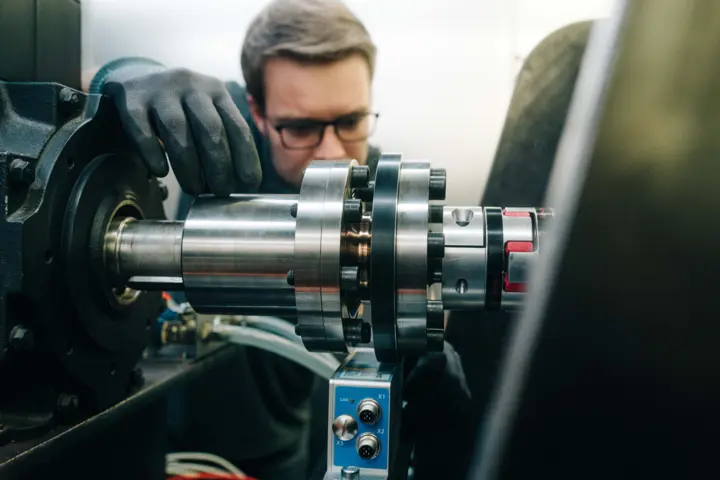

DeepDrive, a trailblazing German high-tech company, opts for the KiTorq torque measuring system from Kistler to test electric motors that feature revolutionary motor topology. Kistler's torque sensor – which delivers contact-free measurements – demonstrates its strengths on the test stand to ensure efficient optimization and validation of these high-performance dual-rotor drives.

How can we exploit electric mobility to the full, extend the driving range of electric cars and boost their efficiency? Many developers and observers are still asking themselves these questions – but only a few have come up with answers. DeepDrive, the Munich-based high-tech company, is already one step ahead of the field: founded in 2021, the firm's workforce has already grown to over 70 employees. DeepDrive has raised capital from high-profile backers including BMW i Ventures and Continental's Corporate Venture Capital (CVC) unit, and is involved in development projects at eight out of the world's ten major automobile manufacturers. Thanks to DeepDrive's patented Dual Rotor technology, driving ranges can be extended by as much as 20 percent – and the revolutionary electric motor winding concept cuts the amount of magnet material used by 50 percent.

Maximilian Habersbrunner is the company's Electrical Hardware System Engineer and one of its co-founders. He recalls the early days: “We got to know one another almost a decade ago while we were students at the Technical University of Munich, when we were members of the TUfast Formula Student Racing Team. After having gained around ten years' experience in the automotive industry and large-scale series projects, the time had come for us to pursue our own idea. Munich is an ideal environment for technology start-ups – the networks are great, and there's plenty of know-how around.” DeepDrive definitely sees itself as far more than a mere hardware supplier: it is set to become the category leader in electric motors for the automotive industry and aims to be a fully-fledged technology enterprise with future industrial production on a large scale. Series production of electric vehicle drives is scheduled to begin in 2026, with the first small series set to start in 2025.

![[object Object] The KiTorq torque measuring system, comprising a rotor and a stator, ensures highly dynamic and precise measurements.](https://kistler.cdn.celum.cloud/SAPCommerce_CMSGalleryPreview_96x64/935-337.webp)

![Optimum accurancy at every operating point [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-974e.webp)