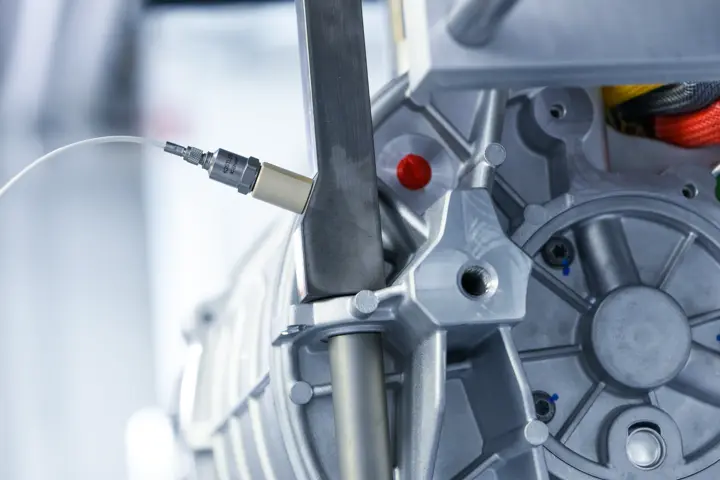

Vibration of motors and powertrains for electric vehicle testing is characterized by high frequency content and the possible presence of current ground loops that can affect the accuracy of its measurement. Triaxial sensors such as the 8763B and 8764B offer an exceptionally broad frequency range and various ground isolation possibilities – all in a wide variety of g ranges, accommodating several NVH testing scenarios. Additionally, accelerometer 8763B ensures flexible mounting and accurate calibration over all three axis, thanks to the three threaded holes - one on each direction. If you need 360° freedom for cable orientation and maximal connection stiffness via screw mounting, accelerometer 8764B fits your requirements, as it features a through hole together with integral ground isolation to minimize current ground loops.

When a single axis measurement is preferred, sensors 8704B and 8774B offer the right performance with a variety of options to optimize your NVH testing on motors and powertrains of electric vehicles.

Noise Vibration and Harshness (NVH) covers all aspects related to the acoustic and vibrational performance of the vehicle and is becoming even more relevant for electric vehicle testing. Good NVH performance of a powertrain or a vehicle translates into durable, reliable and more efficient products, but also driving quality, comfort, and ultimately driving pleasure.

![[object Object] Engine and powertrain NVH testing](https://kistler.cdn.celum.cloud/SAPCommerce_CMSGalleryStandard_720x480/engine-and-powertrain-nvh-testing-48474.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSGalleryStandard_720x480/structural-vibration-testing-and-modal-analysis-48473.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSGalleryStandard_720x480/powertrain-nvh-sensors-for-testing-48472.webp)

![Customized force measurement solutions for powertrain NVH [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-368e.webp)

![Test & Measurement acceleration, acoustic emission and dynamic force [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/900-380e.webp)

![Test & Measurement acceleration, acoustic emission and dynamic force [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/900-380a.webp)

![How measurement technology is advancing vehicle development around the world [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/999-251e.webp)