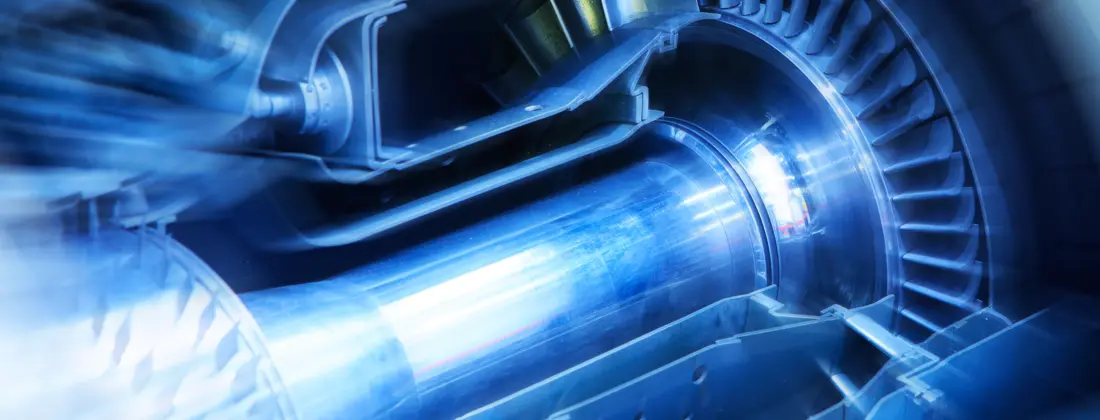

Kistler high-temperature measuring systems allow measuring thermoacoustics phenomena in harsh environments with extreme temperatures up to 700°C.

Lean Dry Low NOx combustion is characterized by potentially highly unstable processes. By means of pressure pulsation and vibration monitoring, combustion dynamics can be kept under control. Kistler sensors allow to measure directly in the combustor and deliver reliable results. Kistler’s modular sensor portfolio is comprised of a variety of sensors, to include Ex-versions certified in accordance with strict ATEX directives.

![Thermoacoustics Technical Brochure – Product Line for Combustion Dynamics on Gas Turbine [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-201e.webp)

![Thermoacoustics – Measuring Combustion Dynamics in High Temperature Environments [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-200e.webp)

![Flyer: High temp accelerometers [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-662e.webp)