New sensor designs for greater precision and longer lifetimes

The trend towards higher mean effective pressures (MEP) is increasing the requirements for the robustness of sensors that are exposed to high pressure levels, high temperatures (of up to 350°C) and vibrations. Kistler is responding to these needs by developing new sensor architectures that combine maximum ruggedness with high accuracy throughout the sensor's lifetime. The Swiss measurement technology experts have now unveiled their cylinder pressure sensor 6635A1: a solution for use in medium-speed four-stroke engines that sets new standards thanks to a host of innovative features.

Resource-efficient and cost-effective operation over long periods

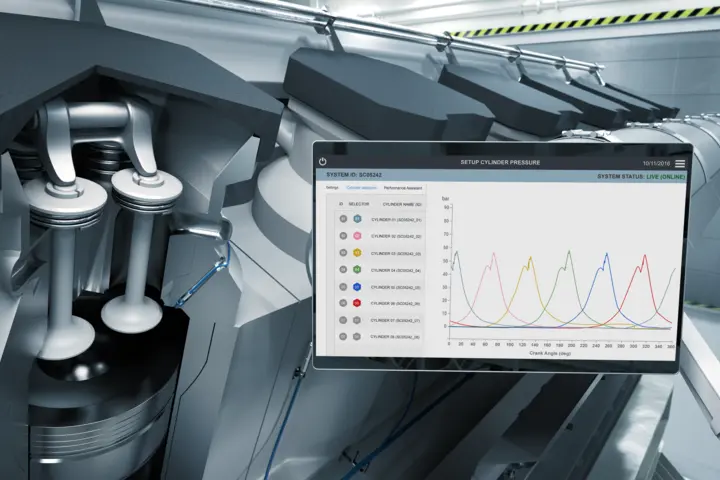

Engine manufacturers across the globe include cylinder pressure sensors from Kistler in their closed loop control systems to optimize engine performance during operation. Continuously monitored pressure in all cylinders is transmitted to an engine control unit: the values are visualized and adjusted accordingly. This Closed Loop Combustion Control (CLCC) yields multiple benefits: the combustion process is optimized, fuel is saved and premature wear on costly parts – potentially resulting in engine failure – is prevented.

Application-specific know-how

Simulation-based development of new sensor concepts is complemented by close collaboration with the engine manufacturer so that the exact installation and operating conditions can be taken into account. When new engines are being designed it is possible to influence key sensor parameters during the development process: these include the installation position in the cylinder, the type of seal and the electrical interface.

One especially important factor is validation of the sensor's characteristics throughout its service life. For this purpose, Kistler has developed its own testing procedures that can replicate heat- and vibration-induced stresses during more than one billion pressure cycles. However, tests on the actual engine are the only way to obtain definitive information about the real performance of the cylinder pressure sensors for CLCC.

Engine power plants are one of the main application areas for cylinder pressure sensors from Kistler. Thanks to CLCC, growing numbers of these plants can operate in dual-fuel or even multi-fuel mode – and even though the use of solar power and wind energy is set to increase in the future, such large plants will continue to play a key part in stabilizing the power grid.

Benefits of solutions from Kistler at a glance:

- Maximum operational reliability thanks to tried-and-tested high-quality products

- Reproducible, high-resolution cylinder pressure measurement

- Precise engine feedback to optimize combustion

- Lower fuel consumption

- Reduced emissions

- Customer-specific solutions for every application

- Ideal for engines with flexible fuel options (multi-fuel)

- Reduced service outlay

- Attractive ROI thanks to long sensor lifetimes