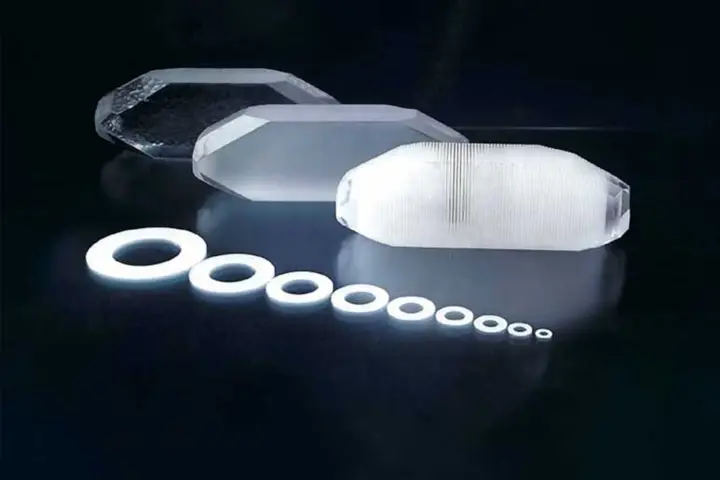

The piezoelectric effect on quartz

The electrical charges that are produced in the piezocrystal are proportional to the force applied and can be used as measurement acquisition signals through the use of a charge amplifier. Unlike many other PE materials, quartz is not pyroelectric and is therefore resistant to temperature fluctuations. In 1950, Walter P. Kistler was granted a patent for a charge amplifier for piezoelectric signals. This paved the way for sensors with excellent measuring properties in dynamic and quasi-static processes.

Applications of the piezoelectric effect

The piezo-effect is the basis for PE sensors with a broad range of possible applications. These include industrial processes such as automobile manufacturing and injection molding, as well as applications in medical technology, aerospace engineering, railway technology, biomechanics, thermoacoustics, and many others. PE sensors form the basis for process monitoring systems with data analysis specifically aimed at obtaining optimal production results.

Advantages of piezoelectric sensors

Depending on the direction of the applied force and the position with respect to the polar axes of the crystal, the PE effect occurs longitudinally (in the direction of the force), transversely (with respect to the force) or diagonally, as a shear effect. PE sensors can, therefore, be integrated into a machine in a variety of ways. PE sensors have certain advantages over strain gauges, including an extremely broad measuring range, overload protection and marked long-term stability – lasting decades in some cases. The piezoelectric effect is particularly convenient for use in so-called IEPE sensors.