The term 'calibration' of a measurement instrument (sensor) or measuring system is sometimes confused with 'adjustment.' When adjusting, the parameters of a measuring system are adjusted so that the desired measurand is displayed correctly.

Why is sensor calibration so important?

Calibration verifies the precision and reproducibility of measurement instruments, such as sensors and measuring systems. Sensors that are calibrated are the prerequisite for precise, reliable and reproducible measurement results. Calibration is one of the key prerequisites for effective quality assurance.

How is calibration documented?

The result of the calibration is documented by means of a calibration certificate or calibration report. By specifying the standards, these documents can verify traceability to national and international standards. The result of calibration is expressed by means of a specification, a calibration function, a calibration curve, a calibration table or a calibration diagram.

What is a recalibration? Why is it essential?

The accuracy of even the most precise and most sensitive measurement instrument or measuring system can deteriorate through wear, aging and environmental influences. It should, therefore, be recalibrated at regular intervals. DIN EN ISO 9001 specifies that a process for test equipment monitoring should be introduced and that the measuring equipment must be calibrated. For this reason, many companies have quality assurance systems that stipulate calibration at regular intervals.

How are sensors for different measurands calibrated?

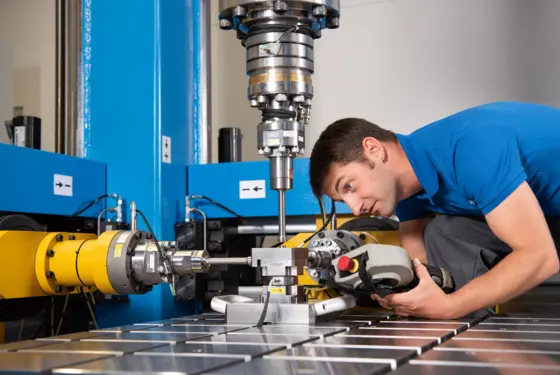

Sensors are calibrated in different ways depending on the measurand. Different calibration processes and calibration machines are used for pressure sensor calibration, force sensor calibration, torque sensor calibration and accelerometer calibration.

What does traceable calibration in an accredited laboratory mean?

Such a calibration is performed in an accredited laboratory in accordance with DIN EN ISO/IEC 17025 and always includes specification of the measurement uncertainty. This standard implements the specification of the International vocabulary of basic and general terms in metrology and ensures the quality of the calibration laboratories. Traceable calibrations are performed in calibration laboratories that are accredited in accordance with DIN EN ISO/IEC 17025. Only such a calibration guarantees the full metrological traceability to national standards.

What details must a calibration certificate include?

- Designation of the test specimen (UUT = Unit Under Test)

- Documentation of the competence of the person responsible

- Documentation of the reference standard and of the traceability

- Documentation of the ambient conditions

- Measurement result, including the measurement uncertainty

- Description and documentation of the applied procedure

- Date: calibrations must be repeated at regular intervals