100 percent quality assurance ensures proven customer satisfaction

To meet the growing demand for shavers and epilators, the company recently built a new production hall. Cutting-edge production technology creates ideal conditions for manufacturing large quantities. But faulty parts can cause costly interruptions on the assembly lines. This is why the company's molding operation concentrates on the high quality of the parts it produces – because this is the factor that determines the functionality of the end products.

The enormous diversity of parts presents a critical challenge: depending on their type, the appliances consist of 200 to 300 individual parts, including 30 to 45 made of plastic. End-to-end quality monitoring is essential for these complex and often highly intricate parts. As part of the internal process control strategy, it was therefore decided to step up consistent monitoring of cavity pressure – with the help of sensors and systems from Kistler.

Since Kistler came on board as the company's partner, inhouse plastic part production has given no cause for complaints. Sensors and systems from Kistler guarantee maximum quality and transparency in the production of plastic parts. They allow measurement experts to monitor cavity pressure during the injection molding process. Steps to implement this technology taken a few years ago have significantly reduced the number of internal complaints. Statistics show a 50 percent reduction in the scrap rate since process monitoring based on cavity pressure was introduced.

The right sensors for every mold

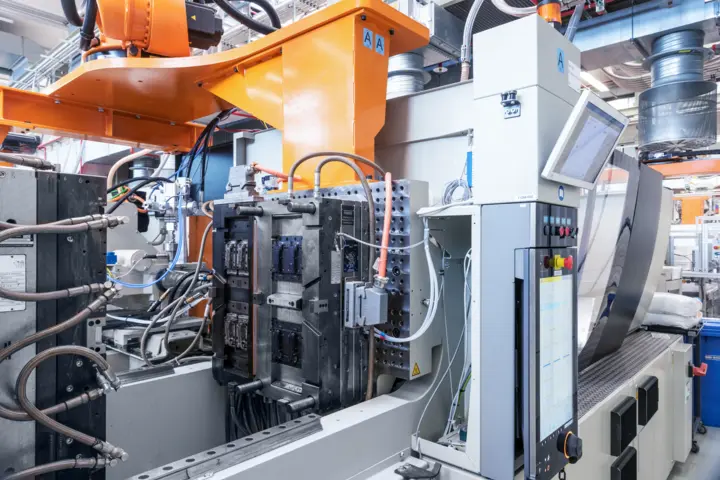

Some 30 process monitoring systems and over 90 molds with cavity pressure sensors are now in operation. The company uses two process monitoring systems: CoMo Injection 2869B and ComoNeo 5887A. They monitor the pressure curves from 2 to 32 cavities. As regards sensors, this manufacturer mostly opts for pressure sensors from Kistler with frontal diameters of 1 mm, 2.5 mm and 4 mm, which are exceptionally rugged and resilient.

In some of the molds, sensors are installed in every cavity but in other cases, the entire mold has only one sensor. However, all the molds are prepared so that each cavity can be retrofitted with sensor technology should the need arise. This allows the process team to decide whether or not to retrofit sensors in the remaining cavities during the debugging phase.

Valuable information about the entire process

Thanks to the deployment of Kistler's sensors and process monitoring systems, the company has seen a vast improvement in quality monitoring and assessment of its injection-molded parts. Cavity pressure profiles supply valuable information about the entire process of creating a part, in correlation with the machine parameters: from the injection phase and the switchover point through to the holding pressure phase in the mold. Targeted monitoring of parameters provides certainty that the quality of molded parts is right. This avoids short shots (when insufficient material is injected into the mold cavities).

The pressure in the mold has to rise above a specified level, but must not exceed a maximum peak pressure. A group of inhouse experts defined these evaluation objects (or EOs, as they are known) during the validation phase. If the pressure curve does not reach the specified minimum level, or if it exceeds the maximum, the process monitoring system assesses the part as non-quality-compliant. This means that it is declared as scrap.

Process monitoring in real time

Immediate separation of bad parts is critically important here. Merely knowing that parts are flawed does not yield any economic benefit. Immediate response and consistent removal of these parts from the production process are the only way to curtail costs caused by machine outages.

The process monitoring systems installed in the plant are simple to operate. The cavity pressure profile can be tracked in real time. The multi-touch display includes features such as trend views so that users can very easily identify any process fluctuations. They can then intervene in the process at an early stage, on the basis of pre-defined warning thresholds.

Cavity pressure monitoring as an early warning system

One key advantage of quality monitoring is the possibility of reproducing processes. In many cases, an injection molding machine is used to produce five or even eight different articles, rather than just one. And even when molds are changed, the pressure profile in the cavity must still behave as defined in the validation. Any influence from external conditions must be excluded. The validated reference curve is the part's 'fingerprint'.

Cavity pressure monitoring is also very important in another way: operators can use the data (visualized as a curve) to assess the condition of their molds and detect wear in good time. So cavity pressure monitoring also acts as an early warning system – for instance, if a pump loses power or if a nonreturn valve is not functioning perfectly.

Reliable, professional service

Once sensors and process monitoring systems from Kistler were in operation, the percentage of short shots decreased significantly. This has given the manufacturer a whole series of positive benefits, so it comes as no surprise that 47 more machines will be equipped with cavity pressure sensors and monitoring systems by the end of 2019 – and Kistler has been chosen as partner and supplier. The good service and on-site support that are so highly appreciated by Kistler's customers are key to the company's plans to expand its monitoring systems. And this leading manufacturer views Kistler's know-how, and the support of its experts in every phase, as essential factors in its future projects.

![CONNECT'20: The customer magazine for consistent process optimization in industrial production [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-410e-02.20.webp)