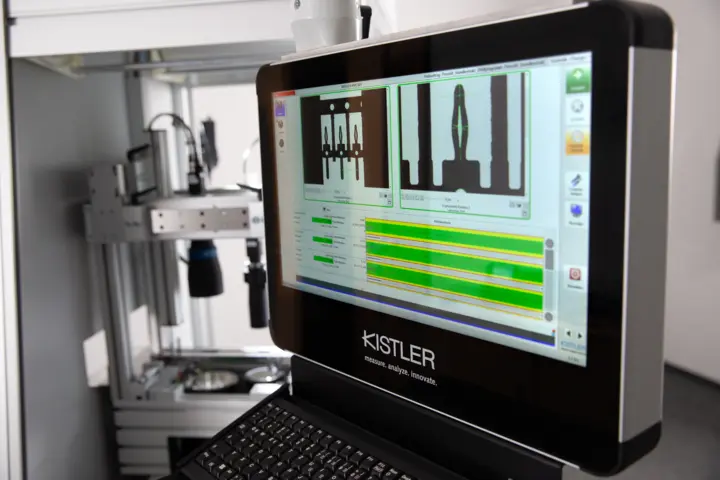

Stamped parts undergo optical inspection in the automated testing system: cameras capture the workpieces from various viewing angles; the KiVision image processing software – developed by Kistler – evaluates the photographs to detect deviations in dimensions or contours as well as relevant surface defects. With KiVision 5.3 and all later versions, users can create their own command macros that make it easier to perform complex testing jobs. Depending on the nature of the tested parts and the requirements, this software also allows anomaly detection based on artificial intelligence. KiVision is especially suitable for use in case of previously unknown surface defects or those that change frequently – such as defects that occur when inspecting weld points, for example.

In continuous operation, the automated system can test as many as 4,000 stamped parts per minute. Even with these cycle times, the integrated safety concepts ensure that the testing process is absolutely reliable. Thanks to rigorous PLC monitoring of the individual processes and the handshake, the automated system is guaranteed to capture and test every single workpiece. The benefit: the KVC 621 SE ensures that only OK parts are wound onto the reels in the downstream process steps – so manufacturers can count on consistent top product quality.

Lifetime advice and support – from initial inquiry to upgrade

Kistler's experts are standing by to assist users throughout the product's lifetime – from the initial inquiry and choice of testing parameters to installation, maintenance and machine upgrades. Our team brings together expertise in all the necessary fields, from mechanical engineering to image processing, and they work hand-in-hand to ensure seamless support. This also includes tailored on-site training and advisory services for employees.

What's more, users benefit from straightforward remote maintenance: if the automated system has a LAN connection, Kistler's technicians can quickly and efficiently support and check all electrical components – with no need to travel to the customer's site. The advantages: higher machine availability combined with lower maintenance costs.

![KVC 621 SE: the new compact testing solution for mass-produced stamped parts [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/999-272e.webp)