Zero-defect production is the success factor

Responsibility for ensuring troublefree production is shouldered by Feller's Group Automation Manager Peter Suter. He knows that zero-defect production is key to market success:

"Quality requirements are constantly on the increase."

Peter Suter, Group Automation Manager, Feller AG

Acceptable reject tolerances have become tighter over the years, setting ever higher requirements for continuous process improvement and the quality testing it entails.

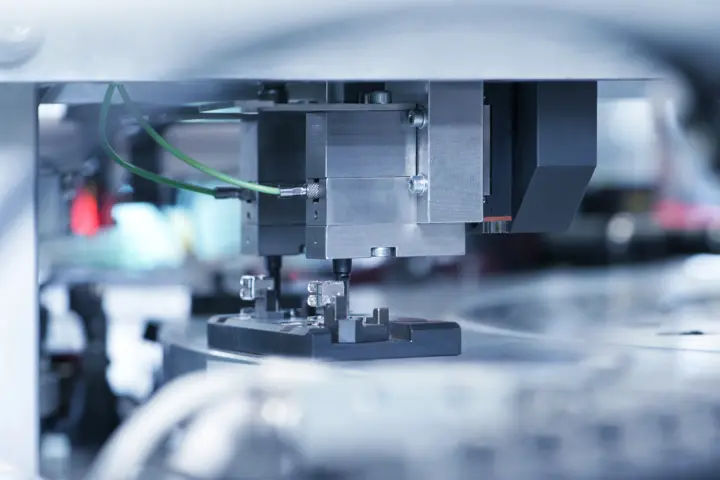

The objective of Feller's fully automated process is to carry out a final inspection on every single product. In 2008, Feller faced a major challenge when a new standard for switches and sockets was introduced in the Swiss energy market. The firm responded to these new regulations by setting up an entirely new production line.

Suter recalls: 'One requirement for the new production line was to guarantee quality standards using force/displacement monitoring. This was included in the design specification for the mechanical engineer. Insys of Münsingen proposed using Kistler technology to monitor caulking of the rocker switch. The new production line – equipped with Kistler sensors – was commissioned in 2008.'

Kistler: the partner of choice

Then in 2011, continuously increasing quality requirements posed a new challenge: as well as monitoring the rocker switch caulking, it was now necessary to test the switch functionality after assembly. Suter explains: 'We had to add an extra step to the switch production process so that the switching point can be tested again. The aim was to avoid additional costs due to switches that are less than 100% correct.'

If any switches fail to function as intended, or if too much force is needed to operate them, this test excludes them from the process directly. The solution for this second application was custom-developed by Feller. The firm was already satisfied with Kistler's monitoring solution, so Kistler technology was the natural choice for the new test function.

However, the initial results were less than optimal due to the pre-existing installation scenario. Low Force sensors were then installed to create a closed system that now delivers reliable, reproducible values and raises quality assurance to new heights. Feller reports a successful outcome: highly efficient production with 100% proven good parts.

![Quality Assurance in Industrial Production Reproducible Quality with Kistler Force-Displacement Monitoring [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-191e.webp)