How to measure cutting forces in turning processes

Turning – and longitudinal turning in particular – is a model case for machining with a geometrically defined cutting edge; because the edge is constantly engaged in cutting, it is used to determine and characterize specific forces for certain materials subject to different boundary conditions.

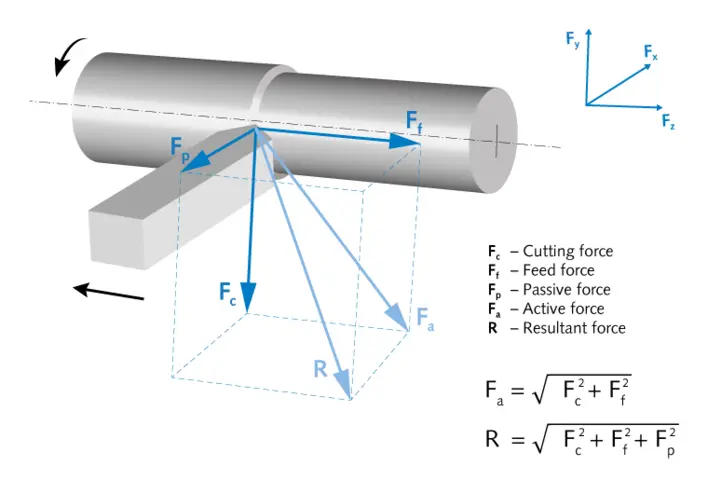

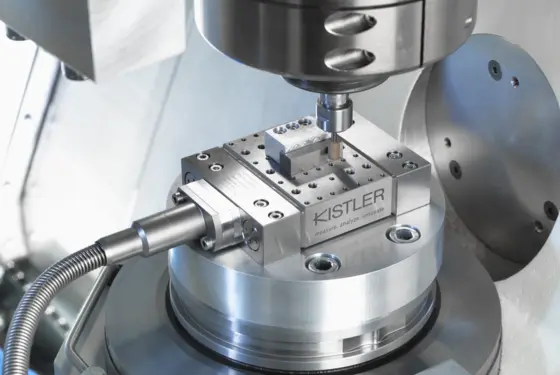

To optimize measurements of the cutting force and the other force components, the tool is clamped onto a stationary dynamometer that operates with piezoelectric technology (see Fig. 3). These dynamometers have a partially modular structure; they are usually mounted on the machine tool’s turret head with the help of a suitable adapter. The tool is mounted on the dynamometer with a tool holder, so the dynamometer is embedded between the tool and the turret head. This structure allows accurate and highly dynamic force measurements so that even the smallest changes in the process chain can be quantified immediately. With the help of multi-component dynamometers, the cutting forces can be measured in terms of three components: cutting force Fc, feed force Ff and passive force Fp.

Advantages of measuring cutting forces in turning processes

Measuring the cutting forces in turning processes pays off in a variety of applications, e.g.:

- Investigation of plastic-mechanical behavior in the actual cutting process

- Analysis of chip formation and its impact on the process

- Identification of wear processes with force progressions

- Understanding material behaviors and thus compare machinability

- Identification of machine/process abnormalities

- Understanding and optimization of machine and process parameters such as chucking, coolants, machine tool stiffness

- And of course by understanding and optimizing the machine and process, one can improve important KPIs such as quality, lead times, cost, environmental impact