How to measure cutting forces in drilling processes

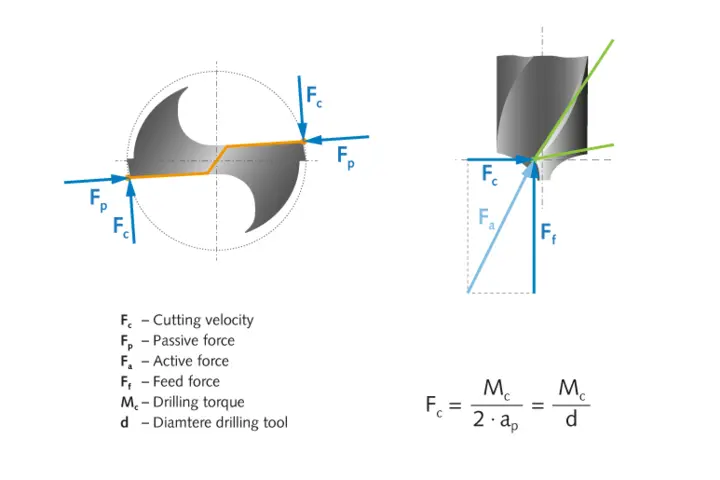

To measure the process forces during drilling, both stationary and rotating dynamometers (RCDs) can be used. An RCD is inserted directly into the machine spindle, while the tool is connected to the RCD with suitable tool holders (see Fig. 2 and Fig. 4). Because it is connected to the machine spindle, the RCD rotates with it during operation (see Fig. 3). The cutting force Fc can be calculated easily with the help of measured Mz and the diameter of the tool.

While using a stationary dynamometer, the workpiece is attached firmly to the dynamometer.

Whether to use a static or rotating dynamometer for measuring the cutting force, depends on the requirements. If the drilling moment is aimed to be measured directly, then an RCD must be used. With the stationary dynamometers, the drilling moment can only be calculated by using the measured orthogonal force components.

Why measure cutting forces in drilling operations

Drilling generates exceptionally high thermal loads on workpieces and on the tools. Moreover, force measurements give an understanding of the tool wear mechanisms, machine-process abnormalities. Thus monitoring and control of the forces will improve the process. Especially when safety-critical components are involved, process analysis based on measurements of process forces is the key factor that ensures maximum production reliability.