Fast, accurate press-fit processes thanks to force control

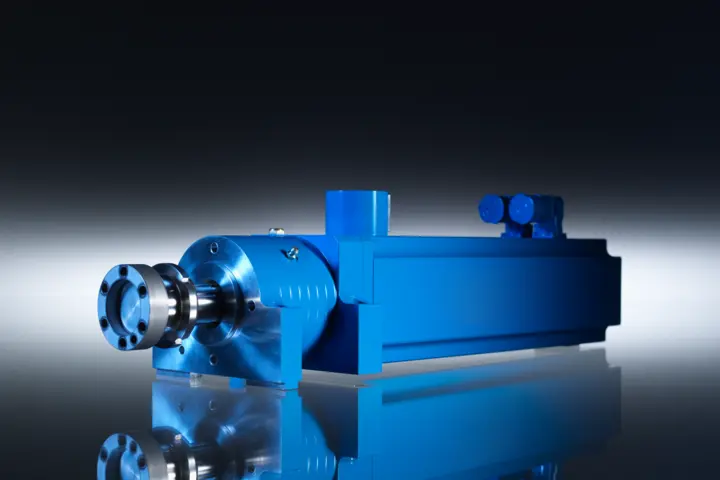

The NCFH joining module is just one member of Kistler's portfolio comprising a total of six series of electromechanical products. Thanks to the integration of a hollow-shaft motor, the Swiss measurement technology experts can offer their industrial customers a module that combines compact design with exceptionally high dynamics – ideal for fast cycles in highly automated environments. Outstanding features of the NCFH also include:

- Precise process control by maXYmos NC

- Fast commissioning thanks to pre-inspection and simple operation

- Constant and high movement speed via direct drive (up to 700 mm/s)

- High positioning accuracy with active deflection compensation

- Two sizes to ensure flexible use and reduced cost of stocking spare parts

- No need for IPC with special software

- Exceptionally low maintenance

For both sizes, the piezoelectric compression and tensile force sensor allows two different measuring ranges to be set – thus ensuring high measurement accuracy as well as additional overload protection, enabling the NCFH series to cover a wide measuring range from 1 to 60 kN.

Consistency, flexibility and transparency for Industry 4.0

When combined with the matching maXYmos NC process monitoring system from Kistler, the NCFH joining module offers high-precision execution of press-fit processes with repeat displacement accuracy of 0.01 mm. Standard functions supported include block pressing, position pressing and force feedback controlled pressing as well as intermediate positioning. Real-time communication between the integrated servo amplifier and maXYmos NC via SERCOS III allows fast process control for short cycle times thanks to a transmission rate of 4 kHz. Various fieldbus interfaces are available for integration into the production environment (PROFINET/PROFIBUS, EtherCAT, Ethernet/IP etc.); additional sensors of different types can also be connected to maXYmos NC – thus helping to standardize the production line with no need for additional hardware.

The NCFH module can be installed both vertically and horizontally; for added flexibility, several joining modules can also be combined and controlled so that complex assembly processes can be mapped. All the joining systems deployed can be centrally visualized and operated with the maXYmos NC modules. Consistency and transparency in keeping with Industry 4.0 are ensured by data transmission to higher-level systems via OPC-UA, or other protocols available as standard such as IPM, QDAS®, XML, PDF, CSV and QDA9. With the help of the maXYmos NC display module, the requirements and quality criteria for all joining processes can be set and visualized rapidly and flexibly.