Winterthur, August 2018 – Vester Elektronik GmbH of Straubenhardt, Germany, joined the Kistler Group in August 2017. Vester offers numerous advantages that benefit Kistler's customers: innovative measurement technology, complete test and sorting systems for quality assurance aided by image processing software – and a wide-ranging stock of technological expertise.

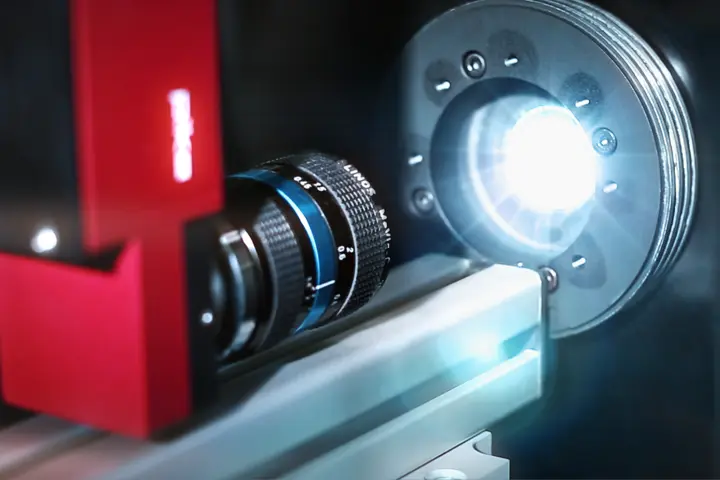

Reliable and troublefree production processes essentially depend on the functional safety and reliability of technical structures, equipment and plant, and on monitoring these elements. Ever since Vester was founded 50 years ago, this family firm has pursued one mission: to prevent errors in the production process with the help of efficient control systems. To accomplish this mission, two business divisions have developed at Vester as the years have gone on. Sensor Technology and Process Monitoring handles the company's traditional business activities, with the addition of lighting components for Vision systems, while Vester's second business division focuses on Test Automation.

In the Sensor Technology and Process Monitoring division, the objective is to prevent disruptions by deploying sensors – mainly IR and laser light barriers as well as control systems – that ensure safe, reliable and troublefree punching and forming processes. The benefits: malfunctions in the punching process can be prevented, so costly consequential damage such as tool breakage is avoided. Vester's Test Automation division concentrates on 100% quality control for zero-defect deliveries, as well as part marking to ensure traceability throughout the production path.