Benefits

- 100% quality assurance

- Optimize cycle times

- Cut staff costs

- Cut energy costs

- Optimize ROI

![Ensuring the quality of composites [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSHeading_1100x420/kistler_composite_quality_assurance_by_rtm_process_monitoring_and_control.webp)

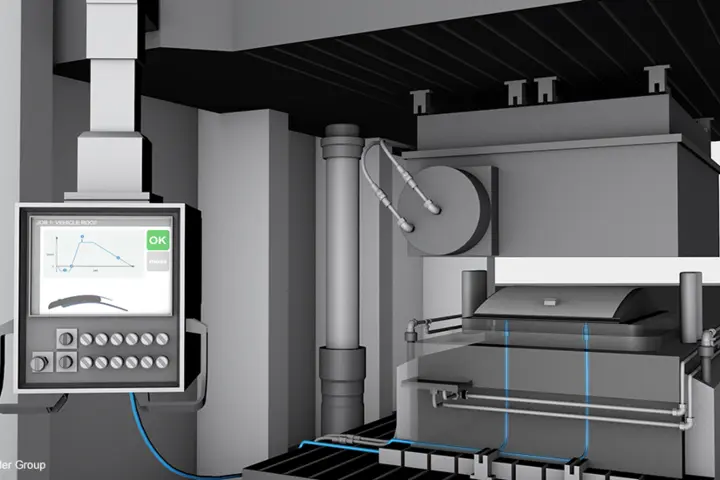

In lightweight component production, optimal processing of fiber composites (e.g. carbon) is essential for success. The resin transfer molding (RTM) process harbors potential for large-scale industrial manufacture so that component production becomes cost-effective.

Comprehensive, dependable monitoring of the pressure inside the cavity – including upstream mold evacuation – is the key to controlling the RTM process and ensuring the required level of reliability. Thanks to our piezoelectric or piezoresistive pressure sensors and charge amplifiers, stable control of cavity pressure and thus of composite part quality, is guaranteed.

Advantages of cavity pressure systems from Kistler for quality assurance in the production of composites:

We're looking forward to working with you. Simply contact us.