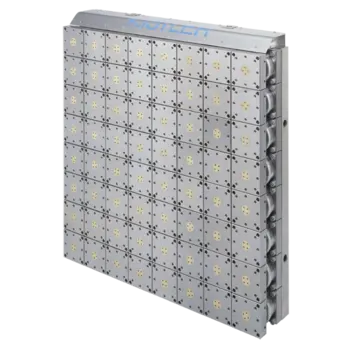

Standard crash wall segments, SmartCrash system, triaxial force measuring elements / 9655B

9655B

The SmartCrash standard segments with triaxial force measuring elements and integrated electronics for data acquisition and storage were developed to measure forces during vehicle crash tests for full width or medium overlap (40%) configurations.

主要特点/优势

- Single connecting cable per segment

- Ideal for dynamic measurements thanks to high rigidity and high natural frequency

- Wide measuring range

- Excellent linearity and high degree of overload protection

- Integrated data acquisition and storage

- TEDS functionality

- Preloaded and calibrated

The SmartCrash force measuring element consists of a top and base plate, the piezoelectric quartz sensor preloaded by a hollow expansion screw between base plate and top plate and an integrated electronics for data pre-processing. Each individual SmartCrash force measuring element measures the 3 orthogonal forces Fx, Fy and Fz of the forces affecting during the crash. The piezoelectric sensor in the force measuring element generates a proportional charge on the force, which is amplified and processed. A unit for digitization of the analog signals (DiMod module) is incorporated in each individual SmartCrash force measuring element. The charge signals are converted into a voltage signal, digitized by an A/D converter and stored in a central data recorder which simultanously executes the parametrization and control. Before the actual measurement is performed, an automatic system check is carried out to check that the entire measuring chain is operating properly. The individual force measuring element is connected by a corresponding connection cable to the data recorder via an RS-485 interface. The SmartCrash force measuring element is supplied calibrated and ready to be used for measurements immediately after being mounted. The power supply for a SmartCrash force measuring element is provided by the power unit or an industrial PC (controller).

正在加载

正在加载