Measurement of rolling resistance on a tire of a NEV – the RoaDyn S220 measuring hub from Kistler (highlighted in blue) used to measure the rolling resistance of a passenger car tire (C1) on the tire test stand. It captures wheel forces using the high-precision force measurement method as specified by the currently applicable standards: ISO 28580, SAE J1269, and ECE R117.

轮胎行业必须面对越来越多的要求,这些要求也适用于轮胎开发商和制造商在其轮胎测试中使用的测量系统。汽车轮胎必须满足越来越高的期望,必须符合更严格的国际标准。重点是油耗和噪音排放,以及更严格的安全和环境标准。这导致轮胎的批准数量持续全面增长,因为每个车型的设备变体数量不断增加,也反映在轮胎的不同选择上--导致原始设备制造商的个别规格。此外,每个汽车制造商都会优先考虑不同的轮胎特性,如转向性、运动性能或乘坐舒适性。

电动汽车也对轮胎规格提出了新的要求--由于电动汽车的重量增加和扭矩增大,以及其他原因。更高的负载要求轮胎具有更高的侧向刚度,而且制动距离也会延长。较低的滚动阻力有助于提高能源效率,从而增加车辆的行驶里程。更低的噪音排放意味着乘客舱内的舒适性--现在内燃机的噪音已经消除,这一标准变得极为重要。然而,启动时的即时扭矩会导致更快的磨损和/或降低运行性能。

对 "量身定制 "的轮胎有需求。灵活的测试能力和更短的测试时间是保持竞争优势的关键。

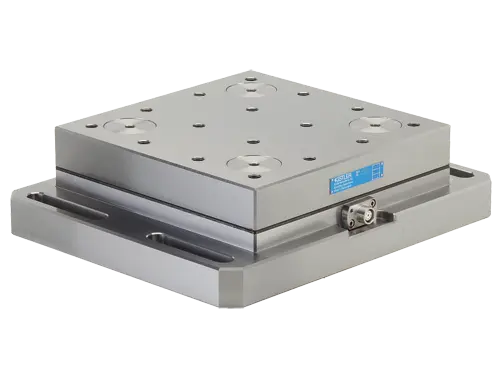

![9289A113型RoaDyn S260测量轮毂 [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSGalleryStandard_720x480/roadyn-s260-measuring-hub-48476.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/kistler_5167A81_16_9.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/933-579_web.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/936-164.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/934-600.webp)

![车辆动力学与耐久性 [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-252c.webp)

![Rolling resistance measurement on tire test stands [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/200-614e.webp)

![Vehicle dynamics, durability and tire testing: product brochure [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-252e.webp)

![How measurement technology is advancing vehicle development around the world [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/999-251e.webp)