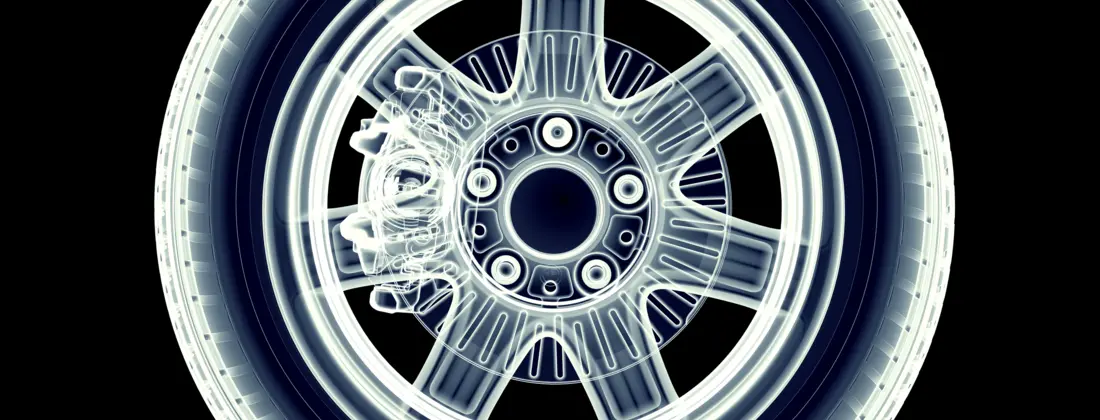

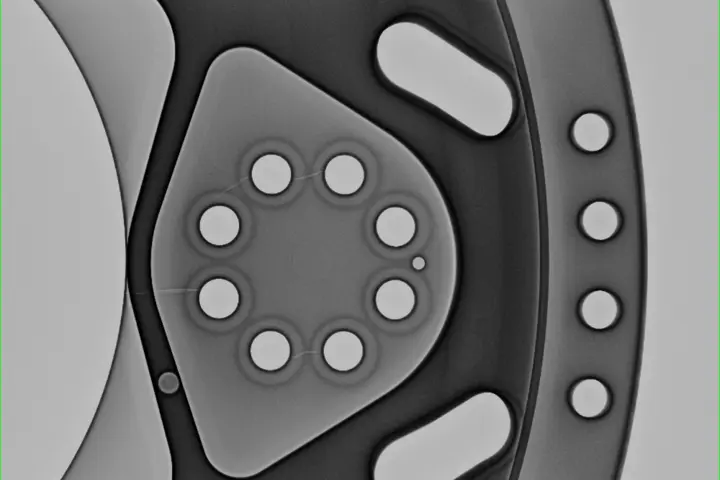

Detect faults quickly with non-destructive testing (NDT) digital radiographic testing and fluorescent dye penetrant testing (PT)

To identify weak points such as minute cracks or pores in the volume or on the surface of materials, we use two different non-destructive procedures:

- Digital radiographic testing – also known as digital radiography (DR) – as per DIN EN 13068-3

- Fluorescent dye penetrant testing (PT) as per DIN EN ISO 3452-1

Your key benefits from non-destructive testing (NDT) of materials by Kistler, Stuttgart:

- In-depth testing of your parts by experts certified to DIN EN ISO 9712

- Standard-compliant test report: contains documentation including detailed evaluation of all findings, based on high-resolution digital radiographs (dye penetrant testing is also documented with images)

- Exceptionally short lead times: we will test your parts within a few working days of receiving the items

Which parts can we test for you?

As a matter of course, we test parts from all manufacturers.

- Non-rotating single components,

such as: cylinder heads, gear casings, crossmembers (subframes), exhaust manifolds, battery mounts/trays, transmission bell housings and similar components - Rotating components such as rims, or our RoaDyn wheel force transducers