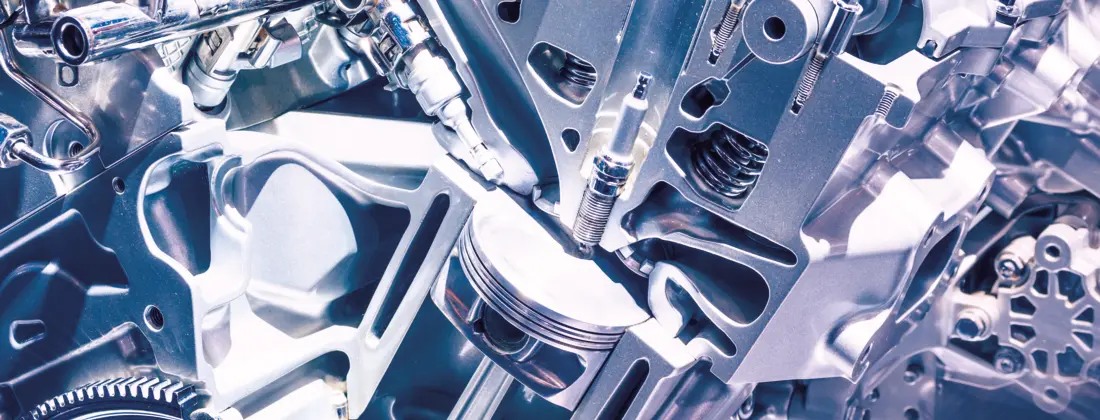

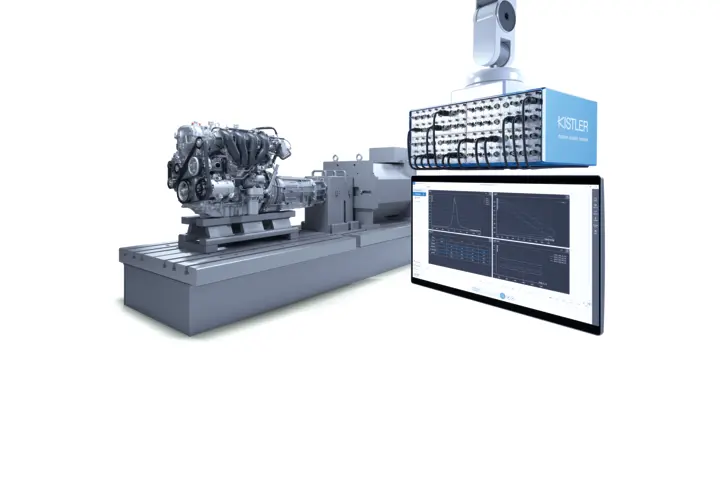

Kistler has more than 50 years of experience in working with customers and providing the most efficient sensors, systems and knowledge for engine combustion pressure analysis. In addition, we have the widest range of sensors and adaptors, to cover the whole engine development process.

Your competitive advantage

Our total solutions for in-cylinder measurements – utilizing state-of-the-art sensing technologies – will help you measure, quantify and optimize your future-oriented combustion systems. This, in combination with our expertise in engine in-cylinder measuring chains, means the path from sensor to answer is shorter and more efficient.

![Engine Indication [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-846e.webp)

![Cylinder Pressure Diagnostics in Large Engines [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/920-685e.webp)

![Pressure sensors and systems [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-310e.webp)

![How measurement technology is advancing vehicle development around the world [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/999-251e.webp)