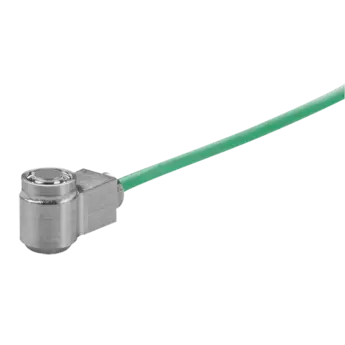

Cavity pressure sensors, indirect measuring (ø3.5 mm, 250 N, 200°C) / 9210A

9210A

These smallest quartz force sensors are suitable for indrect measuring of cavity pressure behind an ejector or measuring pin during the injection molding of plastics.

Main features / advantages

- Minimum size for installation in a mold insert

- Force range: 0 ... 0.25 kN

- Ideal for multi-cavity applications

- Integrated single-wire cable

These miniature versions of the Type 9210AA cavity pressure sensors measure the mold cavity pressure via a measuring pin. This pressure value is obtained from the force measured divided by the area of the measuring pin used. The integral single-wire cable with a very small cross-sectional area is designed to allow flexibility of mounting. With the single-wire technique, electrical shielding is guaranteed by the mold. It is therefore essential for the cable and connector to be integrated into the mold. The charge signal (pC = Picocoulomb) produced by the force sensor is converted into a proportional output voltage in a charge amplifier or a monitor. The maximum possible output voltage at the standard amplifier is 10 V, which corresponds to the maximum pressure value depending on the measuring pin area. For multi-cavity applications, the sensor of Type 9210AAG without connector is used. The multi-channel connectors of Types 1708 and 1710 connect up to 4 or 8 sensors respectively.

Loading

Loading