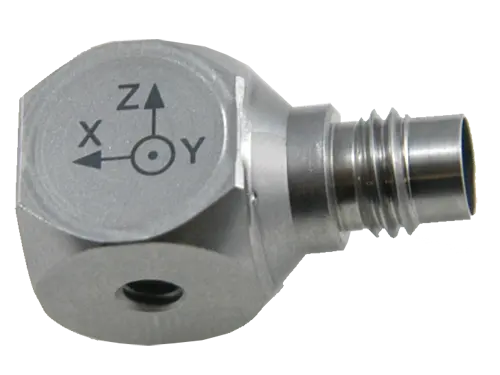

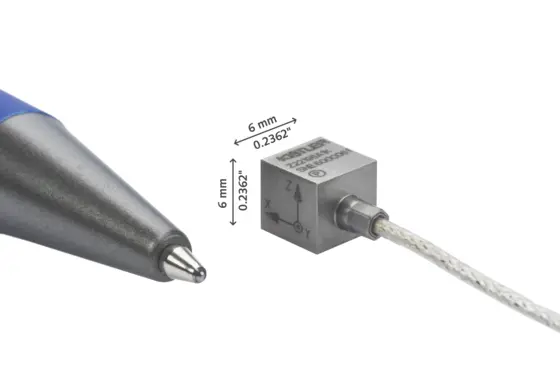

It is necessary to know the impact of force, acceleration and impact orientation when the product contacts the ground. The measurement of high impact forces requires sensors with high stiffness, linearity/low crosstalk errors of the sensor. We provide calibrated single and multicomponent force sensor and accelerometer solutions for precise measurement. Piezoelectric sensors offer considerable advantages over strain gauge sensors that are commonly also used for impact testing.

Unsurpassed precision, long life, wide bandwidth/ fast response time, long-term operational stability, reliability and easy handling during demanding drop testing / impact testing procedures make piezoelectric load cells from Kistler the preferred choice.

Piezoelectric dynamometers to perform drop/impact testing on consumer electronics are typically composed of piezoelectric load cells, featuring:

- Longevity and survivability due to high overload capacity

- Measuring accuracy based on extraordinarily high linearity

- Much higher frequency response of force plate for fast response time (compared to strain gauge technology) thanks to high stiffness

- Externally rangeable with a charge amplifier (e. g. 5018A, 5167A) to optimize the measuring range for the application to best utilize the available dynamic range

You can choose from:

- Multicomponent dynamometers directly off the shelf

- Load cells to build your single and 3-component dynamometers on your own

- 1-component load cells

- 1-component load cell assembly sets with integrated load cells (93x1)

- Custom Product Lane (CPL), the special Kistler service for tailor-made dynamometers and other measurement equipment

As time duration and frequency are inversely proportional, the dynamometer force plate needs to be designed so that the natural frequency is at least 3 to 5 times higher than the expected frequency content of the drop test.

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/93x1C_-_Modellreihe.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/932-477_web.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/Kistler_17.011_5167A81.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/935-883_web.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/931-753n-08.06_web.webp)

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/930-518n-11.02_web.webp)

![Quartz Shear single Axis accelerometers with Cryogenic Options, 500 … 2000 g [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/8730B.webp)