As the core element of the joining system, the maXYmos NC monitors and controls the entire joining process. Sporting an intuitive touch screen display and an integrated sequence control, the system offers exceptional usability and an outstanding degree of flexibility making it suitable for joining process ranging from simple to highly complex. maXYmos NC controls, monitors, evaluates and documents XY curves (e.g. force vs. displacement) for joining and press-fit processes, together with NC joining modules and the IndraDrive servo amplifier that is included in the system. The shape of the measurement curves allows the quality of individual manufacturing steps, assembly groups or even an entire product to be monitored and controlled via SERCOS III in real-time. This means that optimum cycle times can be implemented with maximum repeat accuracy. Since unplanned downtimes are minimized, machine availability and the productivity of the manufacturing process are increased.

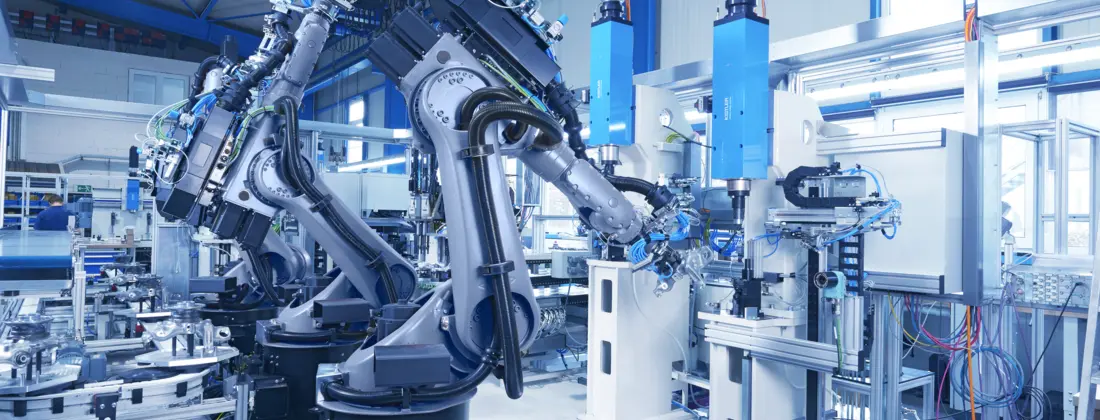

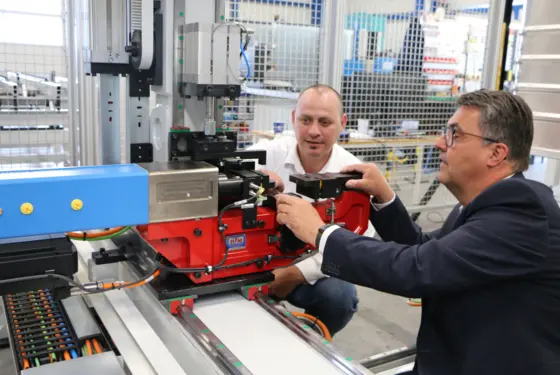

Electromechanical joining systems monitor, control and optimize joining and press-fit operations in the automotive and supply industry as well as convincing by their advantages many other industries like MedTech or white goods. The integrated force-displacement monitoring is performed by maXYmos NC in real time with a complete documentation included.

Our electromechanical joining systems | servo assembly presses are your guarantee of comprehensive quality assurance and process reliability in series production. They help to make cycle times even shorter, reduce scrap and boost productivity.

Special models are available on request – with strokes of up to 1,000 mm, force ranges of up to 600 kN, or angled designs – so you can be sure that the solution you receive will be an exact match for your application.

![NC Joining Modules NCFx and maXYmos NC [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-283e.webp)

![Process Monitoring Systems – maXYmos XY Monitors for 100 % Quality in Production, Assembly and Product Testing [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-338e.webp)

![Joining Competence Center JCC [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-506e.webp)

![Customized service for joining systems [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-627e.webp)