- Full welding process transparency

- 100% traceability and quality control

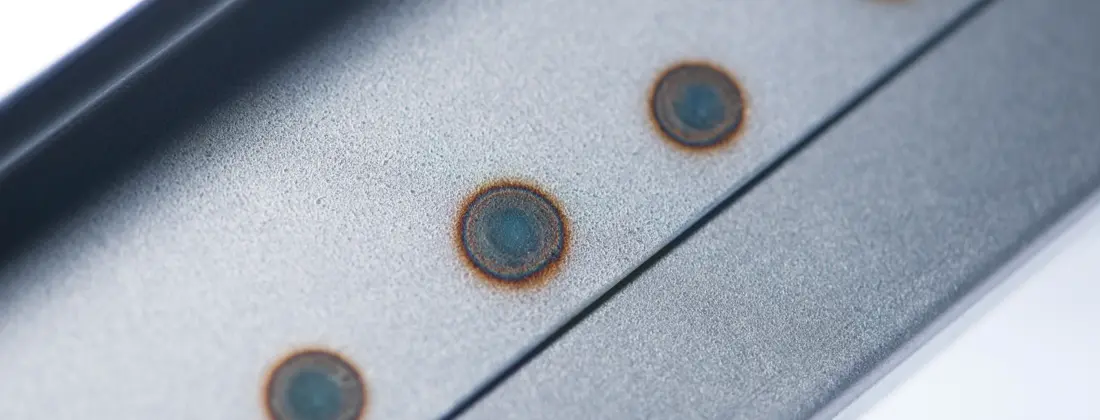

- Zero-defect production

- Piezoelectric sensors are not adversely influenced by electrical/magnetic pulses

- Piezoelectric sensors show no ageing and theoretically have an unlimited lifespan

- Possibility of implementing adaptive, force regulated, welding processes

- Retrofit solutions available

Process monitoring and control that is comprehensive, precise and reliable, is the key factor to ensure stable quality assurance and full process transparency in spot welding. Our sensors can be positioned flexibly – within machine structures, on robotic welding guns, connecting points between push-rods and drives, or even directly in welding gun drives. Individually configurable charge amplifiers and excellent equipment for welding gun calibration round out our portfolio.

![Process Monitoring Systems – maXYmos XY Monitors for 100 % Quality in Production, Assembly and Product Testing [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/960-338e.webp)

![Product Line for Process Instrumentation and Product Testing [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/300-629e.webp)