ComoNeo: pioneering system-based injection molding

Winterthur, October 2018 – The latest version of our ComoNeo process monitoring system ensures high quality, efficiency and transparency in injection molding. Users can choose from a vast range of functions to assemble their own custom monitoring package.

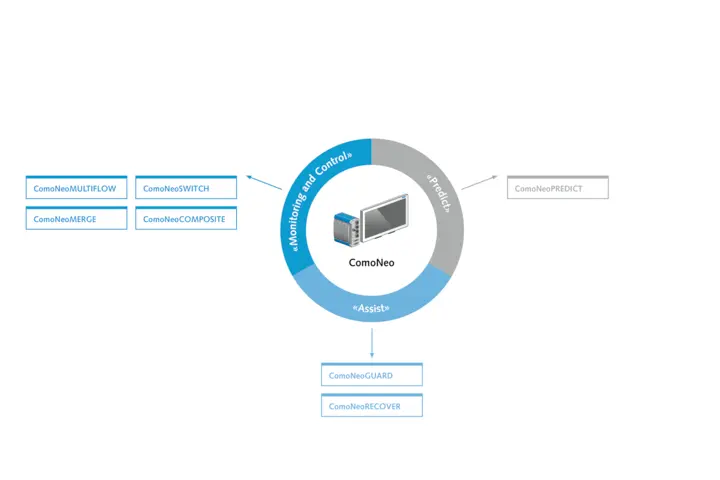

ComoNeo by Kistler: This unique system's combination of complementary functions is the key to individual, holistic optimization of injection molding production.

ComoNeo: custom support guides users reliably to the results they want

One key benefit of this system is its ability to support users according to their individual levels of know-how. Kistler has integrated a practical prediction tool into ComoNeo: the Stasa QC software, which uses measured values and statistical analyses to calculate the quality of manufactured components in advance, and to assess them within tolerance bands. This special process monitoring method is particularly useful for manufacturers of high-grade parts – in medical technology or other sectors where safety is critical, for instance.

To ensure optimal product quality and cost efficiency for their injection molding processes, customers can tailor their own ComoNeo by choosing from these functions:

- ComoNeoPREDICT: Allows model-based prediction of specified part quality based on the cavity pressure and temperature profiles – for optimum process parameters and transparent processes.

- ComoNeoMERGE: When multiple materials are used, process technology becomes more complex – but ComoNeo 3.0 can easily accommodate this challenge. The system monitors and evaluates up to four components with different mold technologies.

- ComoNeoMULTIFLOW: For molds with multiple cavities, this option allows hot runner balancing through individual adjustment of the nozzle temperature – to ensure identical injection conditions in all cavities and automatic correction of deviations.

- ComoNeoSWITCH: This function ensures automated switchover from the injection phase to the holding phase at the ideal time – for balanced injection behavior and optimum mold protection during the process.

- ComoNeoCOMPOSITE: Another new feature: injection molding with the RTM process can now be optimized. Special RTM sensors from Kistler create the conditions for controlled high-quality processing of long-fiber composites.

- ComoNeoGUARD: With this function, users can define monitoring windows to enable accurate separation of good and bad parts on a step-by-step basis. The benefits: guaranteed part quality and less pseudoscrap.

- ComoNeoRECOVER: This feature makes it possible to reproduce a proven injection molding process on a different machine. The user is guided through the adaptation step by step, deviations are identified and the assistant suggests corrective actions.

상담이 필요하신가요?

클릭 한 번으로 전문가를 만날 수 있습니다.