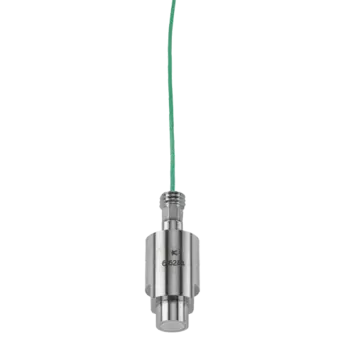

Cavity pressure sensors for low-viscosity thermoset resins (max 200 bar) / 6162A

6162A

These robust piezoeletric cavity pressure sensors measure pressures up to 200 bar during processing of crosslinking molding compounds in various low-pressure methods for lightweight plastic construction in the automobile and aerospace industries.

주요 특징 / 장점

- Suitable for industrial use with conventional and high pressure RTM, LSRs, and SMCs

- Sensitive diaphragm sensor welded into sleeve

- Interchangeable cable

These sensors consist of a sensitive ø4 mm diaphragm design welded into a robust ø6 mm sleeve. The welded ring gap prevents ingress of low-viscosity resins and falsification of the sensor signal by a force shunt. Interchangeable cables allow a choice of cable types and/or repairs. The pressure acts over the diaphragm front of the sensor and is transmitted to the measuring element, which produces a proportional electric charge (pC = Picocoloumb). This is converted into a voltage of 0 ... 10 V in the amplifier, and is then available as an amplifier output. These sensors are available in two versions for different types of cable. The coaxial version uses high-insulation cables that do not necessarily have to be laid in the mold. The practical, singlewire alternative is based on a cable that can be cut to any length. The cut-and-grip connector can be connected during mounting in the mold. This makes both installation and servicing easier.

로딩 중

로딩 중