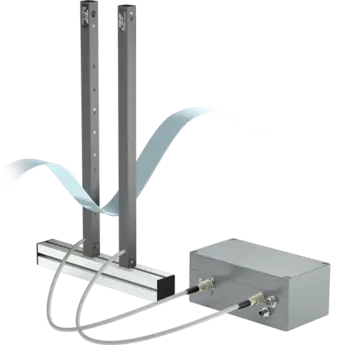

Loop control, sag control, 8 or 16 channels, analog output 0 ... 10 VDC, operating range 50 ... 400 mm / DHS

DHS

The loop control with 8 or 16 infrared light beams detects thin and fast-moving materials when winding and unwinding endless strips.

주요 특징 / 장점

- 8 or 16 separately programmable through-beam sensors

- Operating range between 50 ... 400 mm

- Sensor resolution: >0.2 mm Strip thickness

- Analog output voltage: 0 ... 10 VDC

- Winding or unwinding mode switchable

- Additional switching output for e.g. strip tightening or strip end

- Connection: plug M12, 5-pin

The DHS non-contact loop control for detecting thin materials when winding and unwinding endless strips. With the loop control, stamped strips with a thickness of 0.2 mm or more can be wound or unwound from a reel evenly and without jerks, and thus also without tension and stress. The loop control regulates the drive of the winder in such a way that continuous and vibration-free operation is ensured as a function of the decreasing or increasing diameter of the coils. Eight or 16 infrared light beams are arranged horizontally as through-beam sensors in such a way that only one light beam at a time passes through the material loop of the strip. Trembling movements of the belt do not influence the function. Each light beam can be assigned an output value between 0 and 10 VDC by programming adapter, which is provided at the output as a setpoint for the drive (frequency converter) until another light beam is passed by the belt loop. This ensures continuous operation of the winder drive.

로딩 중

로딩 중