Kistler offers a portfolio of solutions to support the value chain in the injection molding process – ranging from sensor, installation and connection technology to process monitoring and control equipment as well as additional software solutions.

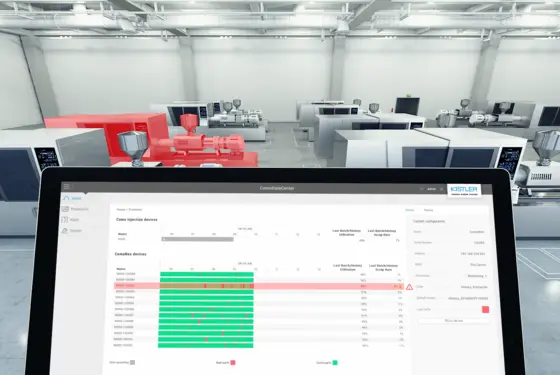

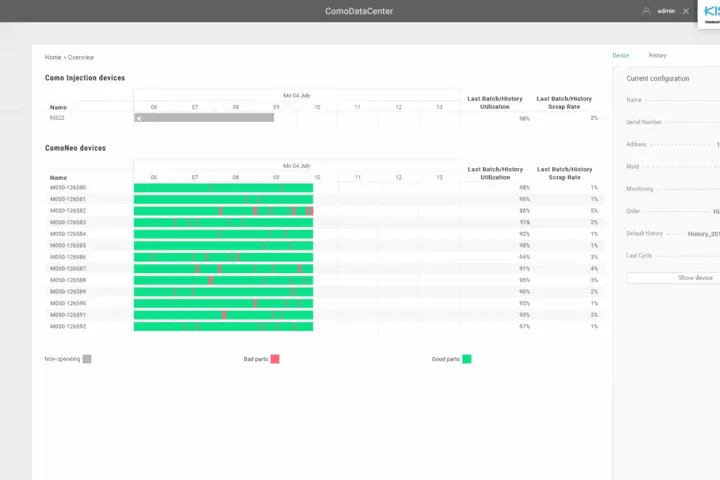

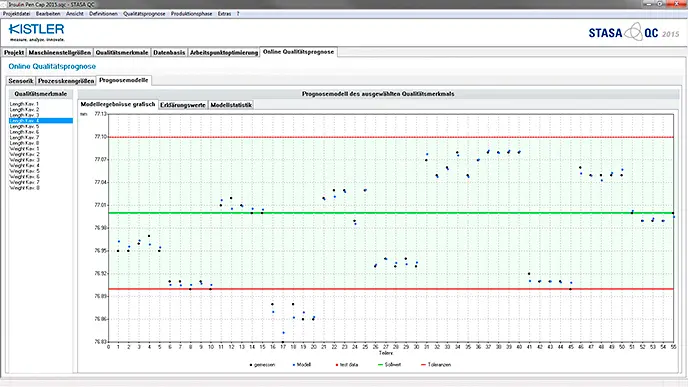

Process data acquired via our monitoring systems contains valuable information. This data – which originates from production – provides the basis for injection molding manufacturers to reach reliable decisions. This is why the data also needs to be stored reliably and made available for visualization as well as further evaluation. Ideally, it is then used for documentation, continuous process optimization, and improvement of the injection molding production process.

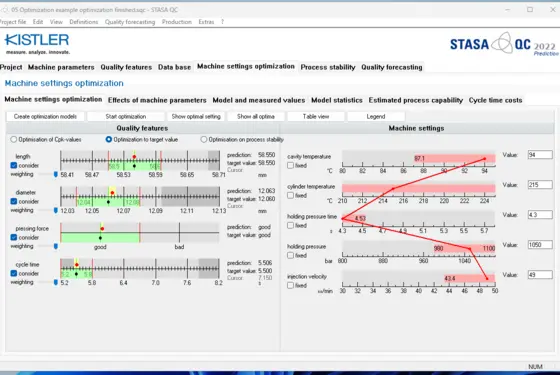

Modern database systems for process data are designed for large quantities of data, and they offer performance matched to their capacity. Machine learning algorithms are increasingly used to extract information based on extensive data: these algorithms also identify complex correlations in line with users' requirements, and process them according to users' specifications. Kistler offers appropriate software systems for all aspects of process data management in injection molding operations. Users of these solutions can be sure of maximum transparency – the key to arriving at sound and reliable decisions.