Charge Amplifier 5074B: Monitoring and optimizing press-fit, assembly and joining processes

Kistler's 5074B Charge Amplifier creates a new standard for industrial charge amplifier technology by offering communication based on Industrial Ethernet (IE) connections. It enables manufacturers to precisely measure very low ranges of charge forces, as small as 0-20 pC, in production such as semiconductor manufacturing. Additionally, digitization of data to EMS systems enables manufacturers to precisely measure every part as it moves through the assembly line, rather than a sample of parts in a metrology lab, so manufacturers can have a better pulse on part quality, which impacts part performance.

With this innovation, plant and machinery manufacturers can integrate piezoelectric sensors directly into a real-time IE system, making Kistler's 5074B Charge Amplifier an ideal choice for monitoring and optimizing a variety of industrial processes, such as semiconductor and medical device manufacturing industries.

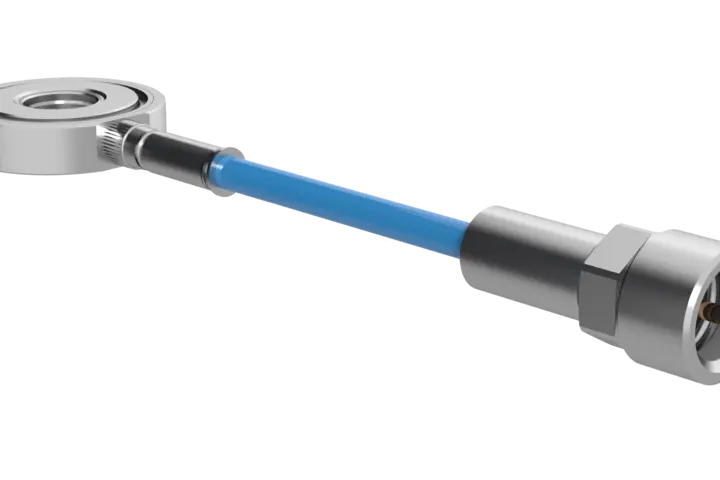

SlimLine 9132CD: Force sensor monitoring for semiconductor production

In response to growing semiconductor production in North America, Kistler recently unveiled its latest force transducer, the SlimLine Force Sensor 9132CD, which boasts a sensitivity nine times higher than comparable SlimLine sensors. Its innovative design, small size and specialized crystal developed by Kistler make it suitable for delivering high-precision measurement for very fine surfaces where force is displaced, such as die sorting, flip chip bonding or other demanding applications.

maXYmos process monitoring systems: New software and firmware primarily for the medical device industry

The maXYmos process monitoring system enables manufacturers to meet a Zero-Defect quality standard. Integrated directly into the production line, this system evaluates process data on each part in real time, eliminating the need for mandatory process validation. The maXYmos NC monitors and controls the process for joining modules and servo amplifiers and is heavily used in the automotive industry for a wide range of manufacturing fitting operations. In addition, Kistler offers the maXYmos TL ML, the first system for the medical device manufacturing sector to provide process monitoring compliant with FDA and MDR regulations. With its ability to monitor and analyze multiple sensor inputs in real time, and its precise control over process parameters, the advanced components are compliant with medical device manufacturing standards.

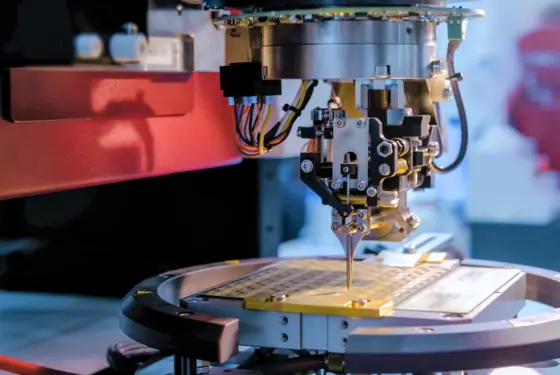

KVC 621: Universal autonomous real-time video measurement for 100% inspection of continuously produced parts as they move through the assembly process

The KVC 621 Vision Inspection System is an autonomous video measurement tool with integrated control and image processing components that focus on high, individually adjustable processing speeds for complex assignments using transmitted and reflected light. Not only does it guarantee parts quality and identify faulty parts, it can also identify potential opportunities to optimize production from 100 percent gauging and inspection of parts, which operates with extreme precision, yielding proven effectiveness and process reliability. Kistler offers different sizes for Vision Inspection units, including a smaller scale option that fits into compact spaces, such as the KVC 621.

Visit Kistler at booth 423 at Automate or its refreshed website to learn more: www.kistler.com. Watch for the new myKistler, a customer self-service e-commerce site launching in 2024.