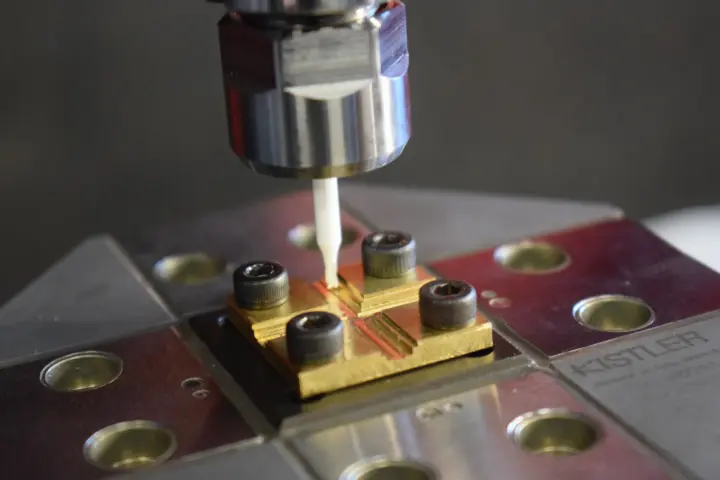

TUSA, the Swiss machining specialist, is testing new microtools made of ceramic at the renowned Polytechnic University of Milan (Politecnico di Milano). This innovative material offers significantly longer lifetimes, but extensive testing is needed to optimize it. MicroDyn from Kistler, the world’s smallest dynamometer, ensures that cutting forces are measured precisely so that performance parameters can be determined.

There’s no doubt that ceramic is an exceptional material – as confirmed by its unique success story. It was used for pottery in the ancient world and then, as porcelain, it came to Europe from China in the 17th century (which is why we still call it “china”); this was followed by the advent of industrial ceramics in the 19th century. And now, the success story is set to continue as new application areas are developed and new material mixes and combinations are researched.

A tool specialist in the southern Swiss canton of Ticino has also begun to focus on ceramics recently: TUSA Precision Tools SA manufactures high-performance machining tools such as those used to make components for watches. Gennaro Teta of Omnino Technology, TUSA’s development partner, explains: “Production of highly intricate components for watch movements has to meet the highest requirements, of course – the tolerances are sometimes in the micrometer range.” Teta’s attention was drawn to the potential of industrial ceramics in his quest for new ways to improve tool life and process reliability for his customers. Watch manufacture is one of the many sectors where the trend is moving towards highly automated, unmanned production. “But what’s the point of being 10% faster if you can manufacture throughout the night at a slightly slower speed – knowing that the process is reliable?” Teta asks. Ceramic material is harder than steel, so it can offer significantly greater resistance to wear as long as the cutting forces are kept under control.

![More robust, with higher precision and longer lifetimes [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_Document_Preview/961-302e.webp)