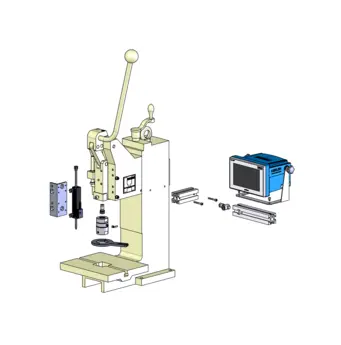

Retrofit sets to equip hand lever presses with force-displacement monitoring / 9819A

9819A

These retrofit kits enable easy upgrading of existing hand lever presses with force-displacement monitoring – for efficient process control and evaluation.

Main features / advantages

- Includes a piezoelectric force sensor of Type 9340A

- Easy sensor integration and simple adaptation of press tools

- Force sensor comes preloaded and calibrated

- Includes configurable maXYmos BL process monitoring system

- Enables process control via maXYmos BL sequencer mode

- Includes various custom accessories such as sensor cables, brackets, etc.

The configurable retrofit kit enables the easy upgrade of hand presses with a force-displacement monitoring system for quality control of processed components. To measure force, a piezoelectric force transducer specifically designed for press applications is used. The force transducer is characterized by a low profile and calibration in multiple force ranges, making it highly versatile in its applications. Furthermore, the force transducer can be easily integrated into the press through suitable adapters. The piezoelectric output signal of the sensor is monitored as a measurement curve, along with the displacement signal, on the subsequent XY monitor. By setting evaluation elements, it is possible to assess and analyze the trends of the measurement curve, enabling the assurance of quality features.

Loading

Loading